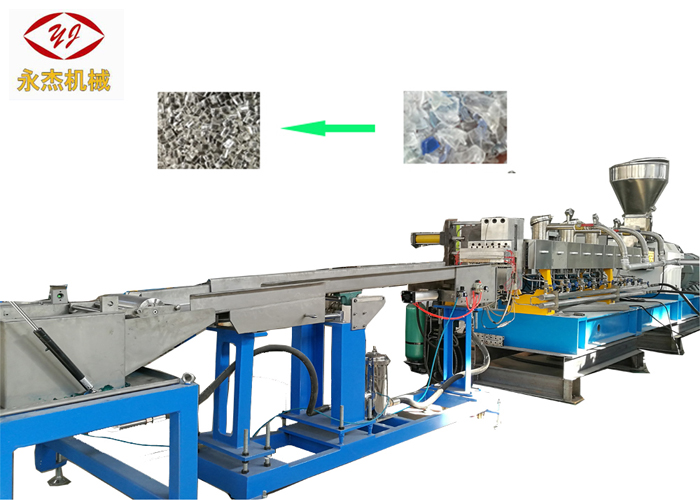

500-800kg/H Dual Screw PET Pelletizing Machine With Water Strand Auxiliary System

| Screw Design: | Twin Screw Extruder | Application: | Pet Flake |

|---|---|---|---|

| Overseas Engineers: | Available For Installation And Comissioning | Screw Diameter: | 62.4mm |

| Screw Material: | W6Mo5Cr4V2 | Motor: | 75kw |

| Rpm: | 300/500 | Capacity: | 200kg/h |

500-800kg/h SJSL95 Doule Screw Pet Recycling Flakes to Granules Machine PET Pelletizing Machine

Nanjing Yongjie started to make water strand twin screw extruder pelletizing machine since 2001,our twin screw extruders are widely used for enforcing modification, degradab le master batch, anti-flame master batch etc.

Models of our twin screw extruder

| Model type | Series | Barrel Diameter (mm) | Screw Diameter (mm) | Screw L/D | screw speed n(r/min) | Main motor power(Kw) | Screw torque T(N.m) | Torque rating (T/A3) | Typical production capacity (kg/h) |

| SJSL20 | A/B | 22 | 21.7 | 32-44 | 500/600 | 4/5.5kw | 30/30 | ||

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Water strand plastic pelletizing machine application

Reinforcement and modification: filling glass fiber or carbon fiber for ![]() P, PA, PBT, ABS, AS, POM, PPS, PET etc.

P, PA, PBT, ABS, AS, POM, PPS, PET etc.

Compounding and blending: PC+ABS, PA,+ABS, PP+EPDM, PA+EPDM, PP+SBS, etc.

Filling modification: filling Caco3, Talc, Titanium, carbon black for PVC, PE, PP,EVA etc.

Cable material: LDE, HDPE, LLDPE, MDPE, drive pipe, insulation material, crosslinking material, cable coating material, thermal contraction material etc.

Special application material: PPR pipe compounds, PE crosslinking tube material, cigarettes filter tip material, acetable fiber material etc.

Thick color masterbatch: PE, ABS, PS, EVA, PET, PP+ pigment + additives, etc.

Flaming retarding material: PVC, PP, PA, ABS, EVA, PBT + fire retardant, etc

Special functional masterbatch: double protection masterbatch, antistatic masterbatch, anti-bacteria masterbatch, thermal insulation masterbatch, hypothermia material etc

The biodegradable masterbatch: PP, PE, PS+ starch + additives etc.

Quick details of the machine

Screw diameter:93mm

Barrel diameter:94mm

Power:280kw

Barrel&screw material:W6Mo5Cr4V2 high speed tool steel

L/D:40:1

Length of barrel:360*10 section=3600mm

Gear box input speed:1480rpm, output 300-400rpm

Reduction ratio:3:1

Special screw array with wear shear of flake material, super power vacuum system to reduce IV loss maximumly.

Scope of supply:

| No. | Contents | Unit | Quantity | Marks |

| 1 | Twin screw extrusion system | set | 1 | |

| 1.1 | Feeding system | set | 1 | 1.5kw |

| 1.2 | SJ-65Twin screw extruder | set | 1 | 280kw, 40:1 |

| 1.3 | Vacuum venting system | set | 2 | 2.2kw |

| 1.4 | Water cycling system | set | 1 | 0.75kw |

| 1.5 | Automatic screen changer | set | 1 | 2.2kw |

| 2 | Electric cabinet | set | 1 | |

| 3 | Water-strand auxiliary system | set | 1 | |

| 3.1 | Die head | set | 1 | |

| 3.2 | Water trough | set | 1 | 6M |

| 3.3 | Dryer | set | 2 | 2.2kw |

| 3.4 | Pelletizer | set | 1 | 1000kg/h, 15kw |

| 3.5 | Product silo | set | 1 | |

| 4 | Documents | set | 1 |

Photos of 500kg/h SJSL95 Pet Recycling Flakes to Granules Machine PET Pelletizing Machine