Best quality Polymer Wood Extrusion Machine - Carbon Black Master Batch Making Machine , 71mm/180mm Polymer Extruder Machine – Yongjie

Best quality Polymer Wood Extrusion Machine - Carbon Black Master Batch Making Machine , 71mm/180mm Polymer Extruder Machine – Yongjie Detail:

| Screw Design: | Twi-single Screw Extruder | Application: | Carbon Black Master Batch |

|---|---|---|---|

| Warranty: | One Year | Color Of Machine: | Any Color Available |

| Screw Diameter: | 71mm/180mm | Motor: | 110/45kw |

| Capacity: | 500-600kg/h | Cutting Way: | Water Ring Hot Cutting |

Carbon Black Masterbatch Machine 71mm/180mm Polymer Extrusion Machine

Quick details

Power:110kw for twin screw exturder, 45kw for single screw extruder

Screw diameter:71mm for twin screw extruder, 180mm for single screw submachine

L/D:48:1 & 9:1

Output:500-600kg/h according to different material, formula and technology of process etc.

Cutting way:water ring

Warranty:one year

Lead time:45 days after deposit

Scope of Supply

| No. | Contents | Unit | Quantity | Marks |

| 1 | SJ75 twin screw extruder | set | 1 | 110KW, 36:1 |

| 1.1 | Screw feeder | set | 1 | 1.5KW |

| 1.2 | Main feeding system | set | 1 | 1.5KW |

| 1.3 | Vacuum venting system | set | 1 | 2.2KW |

| 1.4 | Water cycling system | set | 1 | 0.55KW |

| 2 | YD180 single screw extruder | set | 1 | 55KW, 7:1 |

| 2.1 | Hydraulic screen changer | set | 1 | 1.5KW |

| 3 | Electric cabinet | set | 1 | |

| 4 | Air-cooling assembly system | set | 1 | |

| 4.1 | Die head | set | 1 | |

| 4.2 | Face cutter with cutting wagon | set | 1 | 1.5KW |

| 4.3 | Air cooling cutting cover | set | 1 | |

| 4.4 | Second stage conveying system | set | 1 | |

| 4.5 | Vibrating sieve | set | 1 | 0.4KW |

| 4.6 | First stage product container | set | 1 | |

| 5 | Spare parts | set | 1 | |

| 6 | Documents | set | 1 |

Technical parameter of carbon black plastic granulating production line

technical requirements:

Dynamic data:

low voltage power supply standard(DIN/IEC38): 380v-5+10%, 50Hz-/+2% phase/N/PE50Hz.

control voltage standard (transformed): 220V AC( contactor, meter, electromagnetic valve ).

Temperature:

10-40℃.Humidity: max.80%, no condensation.

Total wattage:~300 KW.

Water requirements:

circulating water: The cooling recycling water in the barrel must be non-inoic soft water (distilled water).

Water sources:

1. Creating a pool (4-6㎥) outside the workshop, using water pump to make recycling water.

2. Using tap water directly, but it’s wasteful.

Weight :Extruder:~8T

Auxiliary system:~2T

Business Clause

Lead time:45 days after deposit

Engineers available for overseas installation, commissioning etc

Payment term:30% deposit via TT, 70% balance before shipment after testing and qualifying machine at seller’s manufacturer, L/C payment are negotiable

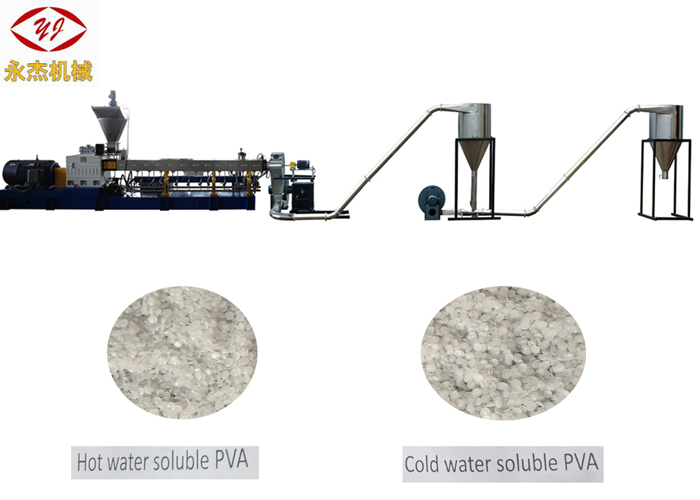

Photo of two stage cable material plastic pelletizing machine

Main technical data of various model of twin screw extruder pelleitizing machine

| Model type | Screw Diameter (mm) | Screw L/D | screw speed n(r/min) | Main motor power(Kw) | Typical production capacity (kg/h) | |

| ZL51-100 | SJSL51 | 50.5 | 20-48 | 500-600 | 37/45 | 150-300 |

| YD100 | 100 | 7-15 | 65-85 | 37 | ||

| ZL60-120 | SJSL60 | 59.5 | 20-44 | 400 | 37/45 | 200-350 |

| YD120 | 120 | 7-15 | 65-90 | 37 | ||

| ZL65-150 | SJSL65 | 62.4 | 20-48 | 400-600 | 55/75 | 250-450 |

| YD150 | 150 | 7-15 | 65-85 | 37/45 | ||

| ZL75-180 | SJSL75 | 71 | 20-44 | 400-600 | 75/90 | 400-650 |

| YD180 | 180 | 7-15 | 65-90 | 45/55 | ||

| ZL95-200 | SJSL95 | 94 | 20-44 | 400-600 | 220/280 | 700-15000 |

| YD200 | 200 | 7-15 | 65-85 | 75/90 | ||

Company Brief

Nanjing Yongjie Qixin Machinery Equipment Co.,Ltd Founded in 2001, covers an area of 20,000 square meters on our own land, with monthly output of machine 20sets. Our factory is certificated to CE, ISO9001:2008.

The company concentrates on research, development and production of “high level, accurate, highly sophisticated series product parallel co-rotating “cordwood” twin screw extruder, single screw extruder, two stage extruders and automatic plastic pelletizing machines. We have provided customers first-class products with “strong torque, high production, energy conservation and environmental protection products. The special designed screw structure has realized successfully for “one step shaping” on many kinds of products, and is widely used in aluminum composite plate, XPS foaming plate, WP plate, PP, PE sheet industry, etc.

Product detail pictures:

Related Product Guide:

Cooperation

Our products and solutions are greatly recognized and trustworthy by customers and may fulfill constantly changing financial and social requires for Best quality Polymer Wood Extrusion Machine - Carbon Black Master Batch Making Machine , 71mm/180mm Polymer Extruder Machine – Yongjie , The product will supply to all over the world, such as: Cologne, Puerto Rico, Rio de Janeiro, We have been very responsible for all details on our customers order no matter on warranty quality, satisfied prices, quick delivery, on time communication, satisfied packing, easy payment terms, best shipment terms, after sales service etc. We provide one-stop service and best reliability to our every customers. We work hard with our customers, colleagues, workers to make a better future.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.