China wholesale China Polymer Extrusion Machine Supplier - Automatic Polypropylene Extrusion Machine , Plastic Pellet Making Machine – Yongjie

China wholesale China Polymer Extrusion Machine Supplier - Automatic Polypropylene Extrusion Machine , Plastic Pellet Making Machine – Yongjie Detail:

| Screw Design: | Twin Screw Extruder | Application: | Recycled PET Flake Less Than 20mm |

|---|---|---|---|

| Moisture: | <1% | IV Loss: | 5% |

| Screw Diameter: | 62.4mm | Motor: | 90kw |

| Super Vacuum: | 5.5kw With Two Ports | Capacity: | 200-300kg/h |

Automatic 40:1 Polymer Extrusion Machine Twin Screw Extruder Plastic Pellet Making Machine

Characteristics of twin screw extruder

The screw arrangement are adopted “toy bricks” principle, which assembly according to different machine L/D, different feeding way, different barrel and screw combination, different screen changing and cutting way, different electrical control mode, etc. it meets the features of material and technological process. Give consideration to the plastic universality commonality and appropriability.

Quick details

Power:90kw,others available

Screw diameter:62.4mm

Barrel diameter:63mm

L/D:40:1

Output:200-300kg(500-600kg by our SJSL95)

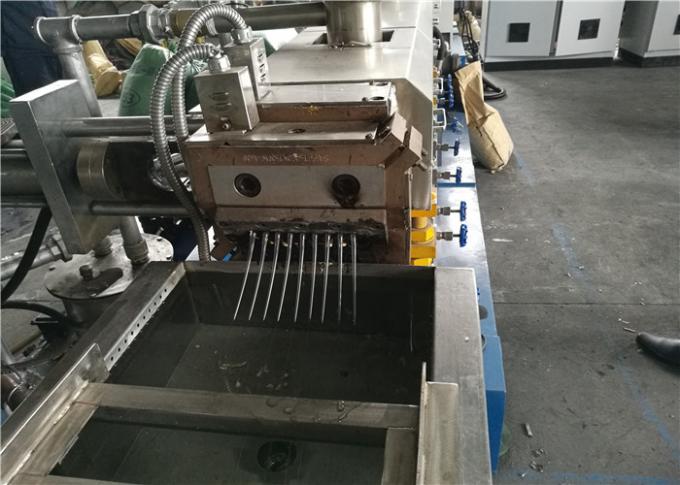

Cutting way: water bath cooling system

Warranty:one year

Lead time:45 days after deposit

Revolution speed:300rpm

Revolution ratio:5:1

Special design : first weak shear of the screw , second increased vacuum system, lower revolution speed of screw as way to maximum decrease the loss of IV of pet

| No. | Contents | Unit | Quantity | Marks |

| 1 | Twin screw extrusion system | set | 1 | |

| 1.1 | Feeding system | set | 1 | 1.1kw |

| 1.2 | SJ-65BTwin screw extruder | set | 1 | 90kw, 36:1 |

| 1.3 | Special Vacuum venting system for PET | set | 1 | 5.5kw, two ports on the fifth and seventh barrel |

| 1.4 | Water cycling system | set | 1 | 0.55kw |

| 1.5 | Automatic screen changer | set | 1 | 1.5kw |

| 2 | Electric cabinet | set | 1 | PID |

| 3 | Water-strand auxiliary system | set | 1 | |

| 3.1 | Die head | set | 1 | |

| 3.2 | Water trough | set | 1 | 4M |

| 3.3 | Dryer | set | 1 | 2.2kw |

| 3.4 | Pelletizer | set | 1 | 300kg/h, 4kw |

| 4 | Documents | set | 1 |

Photo of SJSL65B Recycled PET Bottle Chip Flake Plastic Pellet Making Machine

Main technical data of various model of twin screw extruder pelleitizing machine

| Model type | Series | Barrel Diameter (mm) | Screw Diameter (mm) | Screw L/D | screw speed n(r/min) | Main motor power(Kw) | Screw torque T(N.m) | Torque rating (T/A3) | Typical production capacity (kg/h) |

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Company Brief

Nanjing Yongjie Qixin Machinery Equipment Co.,Ltd Founded in 2001, covers an area of 20,000 square meters on our own land, with monthly output of machine 20sets. Our factory is certificated to CE, ISO9001:2008.

The company concentrates on research, development and production of “high level, accurate, highly sophisticated series product parallel co-rotating “cordwood” twin screw extruder, single screw extruder, two stage extruders and automatic plastic pelletizing machines. We have provided customers first-class products with “strong torque, high production, energy conservation and environmental protection products. The special designed screw structure has realized successfully for “one step shaping” on many kinds of products, and is widely used in aluminum composite plate, XPS foaming plate, WP plate, PP, PE sheet industry, etc.

Main advantages of our recycled PET flake granulating machine

1. Lower IV loss due to good screw array and wear shear of it

2. Clean and white color

Product detail pictures:

Related Product Guide:

Cooperation

We thinks what buyers think, the urgency of urgency to act during the interests of a purchaser position of theory, allowing for much better high-quality, reduced processing costs, charges are more reasonable, won the new and outdated consumers the support and affirmation for China wholesale China Polymer Extrusion Machine Supplier - Automatic Polypropylene Extrusion Machine , Plastic Pellet Making Machine – Yongjie , The product will supply to all over the world, such as: Afghanistan, Slovakia, Tunisia, We have been sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy you with our high-quality products and solutions and perfect service . We also warmly welcome customers to visit our company and purchase our products.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.