Chinese wholesale Polymer Extrusion Machine Sales - Automatic Polypropylene Extrusion Machine , Plastic Pellet Making Machine – Yongjie

Chinese wholesale Polymer Extrusion Machine Sales - Automatic Polypropylene Extrusion Machine , Plastic Pellet Making Machine – Yongjie Detail:

| Screw Design: | Twin Screw Extruder | Application: | Recycled PET Flake Less Than 20mm |

|---|---|---|---|

| Moisture: | <1% | IV Loss: | 5% |

| Screw Diameter: | 62.4mm | Motor: | 90kw |

| Super Vacuum: | 5.5kw With Two Ports | Capacity: | 200-300kg/h |

Automatic 40:1 Polymer Extrusion Machine Twin Screw Extruder Plastic Pellet Making Machine

Characteristics of twin screw extruder

The screw arrangement are adopted “toy bricks” principle, which assembly according to different machine L/D, different feeding way, different barrel and screw combination, different screen changing and cutting way, different electrical control mode, etc. it meets the features of material and technological process. Give consideration to the plastic universality commonality and appropriability.

Quick details

Power:90kw,others available

Screw diameter:62.4mm

Barrel diameter:63mm

L/D:40:1

Output:200-300kg(500-600kg by our SJSL95)

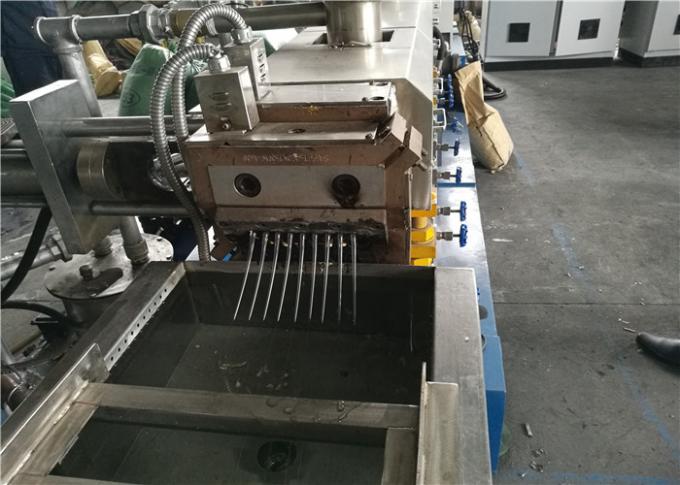

Cutting way: water bath cooling system

Warranty:one year

Lead time:45 days after deposit

Revolution speed:300rpm

Revolution ratio:5:1

Special design : first weak shear of the screw , second increased vacuum system, lower revolution speed of screw as way to maximum decrease the loss of IV of pet

| No. | Contents | Unit | Quantity | Marks |

| 1 | Twin screw extrusion system | set | 1 | |

| 1.1 | Feeding system | set | 1 | 1.1kw |

| 1.2 | SJ-65BTwin screw extruder | set | 1 | 90kw, 36:1 |

| 1.3 | Special Vacuum venting system for PET | set | 1 | 5.5kw, two ports on the fifth and seventh barrel |

| 1.4 | Water cycling system | set | 1 | 0.55kw |

| 1.5 | Automatic screen changer | set | 1 | 1.5kw |

| 2 | Electric cabinet | set | 1 | PID |

| 3 | Water-strand auxiliary system | set | 1 | |

| 3.1 | Die head | set | 1 | |

| 3.2 | Water trough | set | 1 | 4M |

| 3.3 | Dryer | set | 1 | 2.2kw |

| 3.4 | Pelletizer | set | 1 | 300kg/h, 4kw |

| 4 | Documents | set | 1 |

Photo of SJSL65B Recycled PET Bottle Chip Flake Plastic Pellet Making Machine

Main technical data of various model of twin screw extruder pelleitizing machine

| Model type | Series | Barrel Diameter (mm) | Screw Diameter (mm) | Screw L/D | screw speed n(r/min) | Main motor power(Kw) | Screw torque T(N.m) | Torque rating (T/A3) | Typical production capacity (kg/h) |

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Company Brief

Nanjing Yongjie Qixin Machinery Equipment Co.,Ltd Founded in 2001, covers an area of 20,000 square meters on our own land, with monthly output of machine 20sets. Our factory is certificated to CE, ISO9001:2008.

The company concentrates on research, development and production of “high level, accurate, highly sophisticated series product parallel co-rotating “cordwood” twin screw extruder, single screw extruder, two stage extruders and automatic plastic pelletizing machines. We have provided customers first-class products with “strong torque, high production, energy conservation and environmental protection products. The special designed screw structure has realized successfully for “one step shaping” on many kinds of products, and is widely used in aluminum composite plate, XPS foaming plate, WP plate, PP, PE sheet industry, etc.

Main advantages of our recycled PET flake granulating machine

1. Lower IV loss due to good screw array and wear shear of it

2. Clean and white color

Product detail pictures:

Related Product Guide:

Cooperation

No matter new customer or outdated client, We believe in extensive phrase and trusted relationship for Chinese wholesale Polymer Extrusion Machine Sales - Automatic Polypropylene Extrusion Machine , Plastic Pellet Making Machine – Yongjie , The product will supply to all over the world, such as: Serbia, Bahamas, Haiti, Item have passed by means of the national qualified certification and been well received in our main industry. Our expert engineering team will often be ready to serve you for consultation and feedback. We have been able to also deliver you with cost-free samples to meet your specs. Ideal efforts will probably be produced to deliver you the most beneficial service and solutions. Should really you be interested in our company and solutions, please make contact with us by sending us emails or call us straight away. To be able to know our solutions and enterprise. ar more, you'll be able to come to our factory to see it. We will constantly welcome guests from all over the world to our firm. o build business enterprise. elations with us. You should feel absolutely free to speak to us for organization. nd we believe we are going to share the best trading practical experience with all our merchants.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!