Factory Supply Plastic Pet Pelletizing Machine - PID Control Type PET Pelletizing Machine 38CrMoAL Screw / Barrel Material – Yongjie

Factory Supply Plastic Pet Pelletizing Machine - PID Control Type PET Pelletizing Machine 38CrMoAL Screw / Barrel Material – Yongjie Detail:

| Screw Design: | Twin Screw Extruder | Application: | Pet Flake |

|---|---|---|---|

| Cooling System: | Soft Non-inoic Distilled Water | Screw&barrel Material: | 38CrMoAL Nitridge Steel |

| Barrel Diameter: | 22mm | Barrel Length: | 120*7section=840mm |

| Capacity: | 2-5kg/h | Motor: | 5.5kw |

2-5kg/h 20mm Plastic Recycling Machine PP PE PET Recycling Line PET Pelletizing Machine

Yongjie laboratory mini extruder SJSL20 is widely used among our customers of universities, research center, and factory R&D department for the testing of formula, compounding etc.

Quick details

Power:5.5kw

Screw diameter:21.7mm

Screw material:38CrMoAL

Barrel diameter:22mm

Barrel material:38CrMoAL

Output:around2-15kg/h

Cutting way: water strand, air cooling strand also available

Warranty:one year

Lead time:45 days after deposit

Heating power:16kw

Heating zones: 7 zones

Barrel length:120*7=840mm

Control type:PID

Gear box

Transmission gear: Parallel tri-axial structure is combination of reduction and matrix. The gear is made of high quality alloy (20CrNi2Mo). It had been treated by cementation heat process, the precision grade can reach6th. It guarantees the tooth surface is high speed, overloading, low noise and high torque.

Drive bearing: The brand of axletree: Japanese NSK.

Lubrication: Gear bearings in the gear box will be of oil immersed. There is hydraulic lubrication in the gear engagement and gear bearings.

Cooling: Lubricated cooling adopts shell and tube cooler and circulated water cooling method.

Screw

Diameter:¢21.7mm

L/D:40:1

Direction of rotation: Co-rotating

Screw & elements: W6Mo5Cr4V2 (6542#) high speed tool steel that had been treated by the vacuum hardening process with the hardness of the surface is HRC58-62.Molding through dedicated grinding machine. The cleanliness is much better than products out of traditional process.

Core axle: High quality alloy steel 40CrNiMo that with high tenacity and durability. It had been treated by the hardening and tempering process.

Barrel

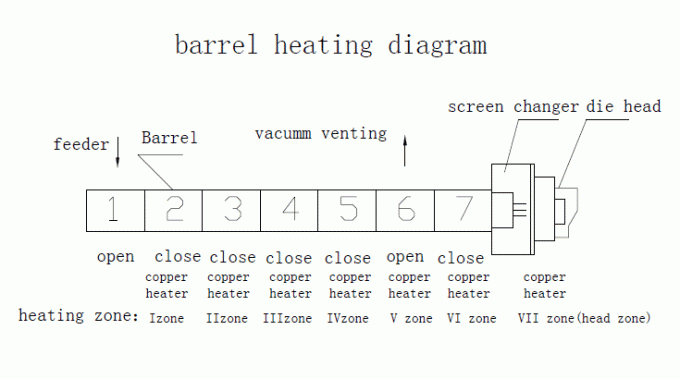

1). Structure: The first section works for main feeding, and the sixth section is set up for vacuum venting, the others are blocked.

2). Material: The material of the barrel 38CrMoAlA, surface hardness: HV950-1050, depth 0.5-0.7mm 3). Heating: Adopt multiple step format electric heating. All zones are cast copper heater. The total heating power is 16KW and the max heating capacity every section can reach

500℃.

4). Cooling: Adopt soft water cooling system in the barrel and tap water cooling way outside barrel. The circulation pipes are made of stainless steel and the water inflow regulating valves are stainless valves.

The brand of electromagnetic valve is DANFOSS.

5). Length: 120*7=840mm

Free spare parts:

| No. | Contents | Unit | Quantity | Marks |

| 1 | Screw elements | set | ~100mm | |

| 2 | Output and input shaft oil seals | piece | 3 | |

| 3 | Venting room seal ring | piece | 1 | |

| 4 | Asbestos gloves | pairs | 2 | |

| 5 | Allen key (inner) | set | 1 | 5 pieces |

| 6 | Allen key (outer) | set | 1 | 3 pieces |

| 7 | Slotted, Philips Screw driver | piece | 1 each | 2 pieces |

| 8 | Copper bar ∮32*200 | piece | 1 | |

| 9 | Screw hoisting ring | piece | 2 |

Photo of Laboratory Mini Extruder PVC Pelletizing Machine Pvc Cable Extruder

Main technical data of various model of twin screw extruder pelleitizing machine

| Model type | Series | Barrel Diameter (mm) | Screw Diameter (mm) | Screw L/D | screw speed n(r/min) | Main motor power(Kw) | Screw torque T(N.m) | Torque rating (T/A3) | Typical production capacity (kg/h) |

| SJSL20 | A/B | 22 | 21.7 | 32-44 | 500/600 | 4/5.5kw | 30/30 | ||

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Company Brief

Nanjing Yongjie Qixin Machinery Equipment Co.,Ltd Founded in 2001, covers an area of 20,000 square meters on our own land, with monthly output of machine 20sets. Our factory is certificated to CE, ISO9001:2008.The company concentrates on research, development and production of “high level, accurate, highly sophisticated series product parallel co-rotating “cordwood” twin screw extruder, single screw extruder, two stage extruders and automatic plastic pelletizing machines. We have provided customers first-class products with “strong torque, high production, energy conservation and environmental protection products. The special designed screw structure has realized successfully for “one step shaping” on many kinds of products, and is widely used in aluminum composite plate, XPS foaming plate, WP plate, PP, PE sheet industry, etc.

How to choose machine for plastic pellet?

1. Just tell us your rough formula?

2. Your expected output per hour of the mahcine

Product detail pictures:

Related Product Guide:

Cooperation

Our commission should be to provide our customers and consumers with ideal top quality and aggressive portable digital products for Factory Supply Plastic Pet Pelletizing Machine - PID Control Type PET Pelletizing Machine 38CrMoAL Screw / Barrel Material – Yongjie , The product will supply to all over the world, such as: Rio de Janeiro, Panama, Guatemala, Each customer's satisfactory is our goal. We are looking for long-term cooperation with each customer. To meet this, we keep up our quality and provide extraordinary customer service. Welcome to our company, we are expecting to cooperate with you.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!