Good Quality China Master Batch Manufacturing Machine Factories - 100-150kg/H Master Batch Manufacturing Machine Water Cooling Strand Cutting Type – Yongjie

Good Quality China Master Batch Manufacturing Machine Factories - 100-150kg/H Master Batch Manufacturing Machine Water Cooling Strand Cutting Type – Yongjie Detail:

| Screw Design: | Twin Screw Extruder | Plastic Type: | PP/PE Etc+pigment |

|---|---|---|---|

| Overseas Engineers: | Available For Installation And Comissioning | Screw Diameter: | 50.5mm |

| Screw & Barrel Material: | W6Mo5Cr4V2 | Motor: | 45kw |

| Cutting Type: | Water Cooling Strand | Capacity: | 100-150kg/h |

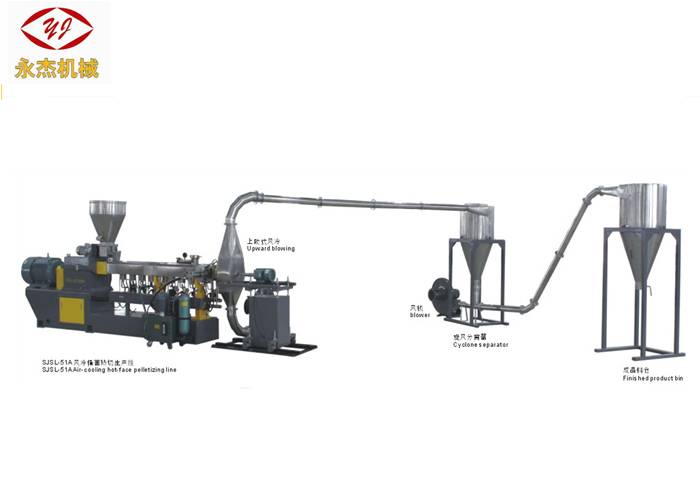

100-150kg/h Twin Screw Masterbatch Machine Master Batch Manufacturing Machine

Nanjing Yongjie started to make corn starch, pla pellets, biodegradable plastic pellets since 2001,our twin screw extruders are widely used for enforcing modification, degradable master batch, anti-flame master batch etc also.

Water strand plastic pelletizing machine application

Reinforcement and modification: filling glass fiber or carbon fiber for ![]() P, PA, PBT, ABS, AS, POM, PPS, PET etc.

P, PA, PBT, ABS, AS, POM, PPS, PET etc.

Compounding and blending: PC+ABS, PA,+ABS, PP+EPDM, PA+EPDM, PP+SBS, etc.

Filling modification: filling Caco3, Talc, Titanium, carbon black for PVC, PE, PP,EVA etc.

Cable material: LDE, HDPE, LLDPE, MDPE, drive pipe, insulation material, crosslinking material, cable coating material, thermal contraction material etc.

Special application material: PPR pipe compounds, PE crosslinking tube material, cigarettes filter tip material, acetable fiber material etc.

Thick color masterbatch: PE, ABS, PS, EVA, PET, PP+ pigment + additives, etc.

Flaming retarding material: PVC, PP, PA, ABS, EVA, PBT + fire retardant, etc

Special functional masterbatch: double protection masterbatch, antistatic masterbatch, anti-bacteria masterbatch, thermal insulation masterbatch, hypothermia material etc

The biodegradable masterbatch: PP, PE, PS+ starch + additives etc.

Quick details of machine

| No. | Contents | Unit | Quantity | Marks |

| 1 | Twin screw extrusion system | set | 1 | |

| 1.1 | Feeding system | set | 1 | 0.75kw |

| 1.2 | SJ-51Twin screw extruder | set | 1 | 45kw, 44:1 |

| 1.3 | Vacuum venting system | set | 1 | 1.5kw |

| 1.4 | Water cycling system | set | 1 | 0.55kw |

| 1.5 | Automatic screen changer | set | 1 | 1.5kw |

| 2 | Electric cabinet | set | 1 | |

| 3 | Water-strand auxiliary system | set | 1 | |

| 3.1 | Die head | set | 1 | |

| 3.2 | Water trough | set | 1 | 3M |

| 3.3 | Dryer | set | 1 | 1.5kw |

| 3.4 | Pelletizer | set | 1 | 4kw |

| 4 | Documents | set | 1 |

World famous brands of electronic components

1). Temperature control meter is Japanese RKC meter, intelligent type, double channel;

2). The inverter of extruder is ABB;

3). The low-voltage apparatus and the button adopt SCHNEIDER product;

4). AC contactor adopt SIEMENS product;

5). The main motor is SISMENS BEIDE;

6). The air switch adopts CHINT products. The solid-state relays are from American joint venture brand;

7). The electromagnetic valve: adopt Denmark DANFOSS product.

Photos of color masterbatch machine

Main technical data of various model of twin screw extruder pelletizing machine

| Model type | Series | Barrel Diameter (mm) | Screw Diameter (mm) | Screw L/D | screw speed n(r/min) | Main motor power(Kw) | Screw torque T(N.m) | Torque rating (T/A3) | Typical production capacity (kg/h) |

| SJSL20 | A/B | 22 | 21.7 | 32-44 | 500/600 | 4/5.5kw | 30/30 | ||

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Product detail pictures:

Related Product Guide:

Cooperation

With this motto in mind, we've got develop into amongst one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for Good Quality China Master Batch Manufacturing Machine Factories - 100-150kg/H Master Batch Manufacturing Machine Water Cooling Strand Cutting Type – Yongjie , The product will supply to all over the world, such as: Uganda, Italy, Japan, We have a dedicated and aggressive sales team, and many branches, catering to our main customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!