Good Quality Plastic Recycling Machine - Underwater PP PE Plastic Scrap Recycling Machine , Single Screw Extrusion Machine – Yongjie

Good Quality Plastic Recycling Machine - Underwater PP PE Plastic Scrap Recycling Machine , Single Screw Extrusion Machine – Yongjie Detail:

| Screw Design: | Single Screw Extruder | Application: | PP PE Scrap Etc |

|---|---|---|---|

| Warranty: | One Year | Screw Diameter: | 220mm |

| Motor: | 280kw | Capacity: | 800-1000kg Per Hour |

| L/D: | 32:1 | Barrel Length: | 7000mm |

YD220 Underwater PP PE Waste Scrap Material Pelletizing Machine Single Screw Extruder Machine

Characteristic of Yongjie single screw extruder

1.High precision gear box with ability of over loading, smooth transmitting, lower noise

2.Newly designed barrel and screw to ensure well-distributed of material in melting, low melt temperature and high production

3.The screw is made with standard and high precision during process. After treated by gases and nitride the barrel, it possesses strong wear- and corrosion- resisting. For special material, double metals are available for barrel etc.

4.The barrels cooled by lower with super mute working status, less maintenance

5.PID temperature is controlled by Japan temperature control meter with stable and accurate temperature.

6.Two type of die head design: manual and hydraulic type for easy changing and time saving.

7.ABB or other famous brand Inverter speed control for more stable and good performance of machine and easier operation

Typical Application

Working for plastic raw material dye, recycling plastic pellets from film, flake, scrap and engineering plastics, such as ABS, PC, POM, PP, PE, ABS/PC, PET etc.

Main technical parameter of YD-220 production line

Screw diameter:φ220mm, L/D:32:1; Screw center height: 1100mm;

screw length: ~ 7000mm; screw and gear box with spline connection;

Screw material: 38CrMoAlA, nitriding treatment, surface hardness: HV950-1050, layer depth 0.5-0.7mm;

| No | Contents | Unit | Quantity | Marks |

| 1 | Screw machine | set | 1 | 2.2kw |

| 2 | Single screw extrusion system | set | 1 | 280kw,32:1 |

| 2.1 | Feeding system | set | 1 | 3KW |

| 2.2 | YD-220 single screw extruder | set | 1 | |

| 2.3 | Automatic screen changer | set | 1 | 1.5KW |

| 3 | Electric cabinet | set | 1 | |

| 4 | Water-ring auxiliary system | set | 1 | |

| 4.1 | Die head | set | 1 | |

| 4.2 | Face cutter | set | 1 | 2.2kw |

| 4.3 | Dehydrator | set | 1 | 11kw |

| 4.4 | Vibrating sieve | set | 1 | 0.75kw |

| 5 | Underwater pelletizing auxiliary machine system | set | 1 | UW1000 |

| 5.1 | Dump valve system | set | 1 | 4kw |

| 5.2 | Cutting head | set | 1 | |

| 5.3 | Cutting knife system | set | 1 | 7.5KW |

| 5.4 | Pneumatic valve | set | 1 | |

| 5.5 | Dehydrator | set | 1 | 11kw |

| 5.6 | Electric control system | set | 1 | PLC |

| 5.7 | vibrator | set | 1 | 0. 75 KW |

| 6 | Free spare parts | set | 1 |

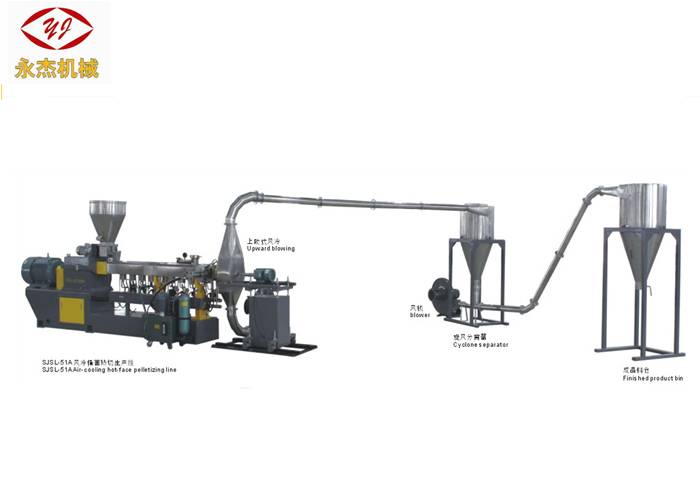

Photo of single screw extruder plastic pellet mahcine

Main technical data of various model of single screw extruder palstic pelleitizing machine

| Model type | Screw Diameter (mm) | Screw L/D | Main motor power(Kw) | screw speed n(r/min) | Typical production capacity (kg/h) |

| YD-30 | 30 | 25-33 | 4/5.5 | 3-100 | 2-15 |

| YD-45 | 45 | 20-32 | 5.5/7.5 | 5-84 | 5-40 |

| YD-60 | 60 | 20-32 | 17.5/22 | 5-84 | 15-80 |

| YD-90 | 90 | 20-33 | 30/37 | 5-84 | 25-120 |

| YD-100 | 100 | 20-33 | 37/45 | 5-84 | 45-150 |

| YD-120 | 120 | 20-33 | 45/55 | 5-84 | 75-200 |

| YD-150 | 150 | 20-33 | 75/90 | 5-84 | 150-300 |

| YD-180 | 180 | 20-33 | 90/132 | 5-84 | 200-400 |

| YD-200 | 200 | 20-33 | 110/160 | 5-84 | 250-500 |

Company Brief

Nanjing Yongjie Qixin Machinery Equipment Co.,Ltd Founded in 2001, covers an area of 20,000 square meters on our own land, with monthly output of machine 20sets. Our factory is certificated to CE, ISO9001:2008.

The company concentrates on research, development and production of “high level, accurate, highly sophisticated series product parallel co-rotating “cordwood” twin screw extruder, single screw extruder, two stage extruders and automatic plastic pelletizing machines. We have provided customers first-class products with “strong torque, high production, energy conservation and environmental protection products. The special designed screw structure has realized successfully for “one step shaping” on many kinds of products, and is widely used in aluminum composite plate, XPS foaming plate, WP plate, PP, PE sheet industry, etc.

QAULITY IS PUT AT THE FIRST , and our factory is certificated to ISO 9001:2008 and CE.

Product detail pictures:

Related Product Guide:

Cooperation

Our company promises all buyers of the first-class products and solutions as well as most satisfying post-sale support. We warmly welcome our regular and new shoppers to join us for Good Quality Plastic Recycling Machine - Underwater PP PE Plastic Scrap Recycling Machine , Single Screw Extrusion Machine – Yongjie , The product will supply to all over the world, such as: Jamaica, Marseille, Costa rica, Taking the core concept of "to be the Responsible". We'll redound up on society for high quality merchandise and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

We have been looking for a professional and responsible supplier, and now we find it.