Babban Performance PVC Pelletizing Machine Don Cable 38CrMoAl Screw & Barrel Material

| Zane-zane: | Twin Screw Extruder | Aikace-aikace: | Pvc Cable Raw Material |

|---|---|---|---|

| Garanti: | Shekara daya | Material Screw: | 38CrMoAL Nit-ridged Karfe Don Anti Corrsion |

| Diamita na Screw: | 50.5mm | Motoci: | 37kw |

| Alamar Mota: | SIEMENS BEIDE | Fitowa: | 50-80kg/h |

Cooling Die Face PVC Pelletizing Machine Application

Ƙaddamar da gyara:PE, EVA da sauransu + Caco3, Talc, Tio2, PVC, PP, Carbon baki

Batch mai ƙasƙanci:PE, PS da dai sauransu + sitaci, ƙari da dai sauransu

Anti-flake master batch:PE, EVA da dai sauransu + Sb2o3, Mg (OH)2, AI2(OH)3da dai sauransu.

Cikakkun bayanai masu sauri

Power: 37kw

Matsakaicin diamita: 50.5mm

Ganga diamita: 51mm

Screw & ganga kayan:38CrMoAl

Fitowa: 100-150kg/h

Yanke hanyar: sanyaya iska mutu fuska don kayan pvc

Garanti: shekara guda

Lokacin jagora: kwanaki 45 bayan ajiya

Ƙarfin zafi: 26kw

Yankunan dumama: yankuna 9

Iyakar wadata

| A'a. | Abubuwan da ke ciki | Naúrar | Yawan | Alamomi |

| 1 | Mai haɗawa da sauri | saita | 1 | |

| 2 | Injin ciyar da dunƙule | saita | 1 | |

| 3 | Twin dunƙule extrusion tsarin | saita | 1 | |

| 3.1 | Tsarin ciyarwa | saita | 1 | 0.75kw |

| 3.2 | SJ-51 Twin dunƙule extruder | saita | 1 | 37kw, 36:1 |

| 3.3 | Tsarin iska mai iska | saita | 1 | 1.5kw |

| 3.4 | Tsarin keken ruwa | saita | 1 | 0.55kw |

| 3.5 | Mai canza allo ta atomatik | saita | 1 | 1.5kw |

| 4 | Wutar lantarki | saita | 1 | |

| 5 | Tsarin taimako na sanyaya iska | saita | 1 | |

| 5.1 | Mutu kai | saita | 1 | |

| 5.2 | Mai yanke fuska | saita | 1 | 1.5kw |

| 5.3 | Tsarin isar da matakai guda ɗaya | saita | 1 | 4 kw |

| 5.4 | Silo samfur | saita | 1 | 4 kw |

| 6 | Takardu | saita | 1 |

Sabis na siyarwa kafin sayarwa

♦1.Taimakon bincike da shawarwari.

♦2.Zaɓar tattalin arziƙi da dacewa masu fitar da injunan da ke da alaƙa ga abokan ciniki.

♦3.Samar da bayanan fasaha na na'ura.

♦4.Samar da hanyoyin gwaji don abokin ciniki.

♦5.Yawon shakatawa na masana'anta & taimako na wasiƙar gayyata lokacin da ake buƙata.

Sabis na tallace-tallace

♦1.Shawarwar yanayin injiniya da ake buƙata don shigarwa.

♦2.Sadarwa akan lokaci matsayin masana'antar inji.

Bayan-tallace-tallace sabis

♦1.Injiniyoyin da ke akwai don injinan sabis a ƙasashen waje a cikin shigarwa, ƙaddamarwa da horo.

♦2.Aiwatar da cikakken bayanin odar abokin ciniki.

♦3.Samar da sabis na kulawa na dogon lokaci da kayan gyara.

♦4.Ba da goyon bayan fasaha ga abokin ciniki don haɓaka sabon samfur.

♦5.Samar da kulawa kyauta na shekara guda.

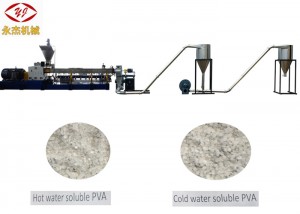

Hoto na SJSL51 50-80kg/h Kayan aikin Extrusion PVC Cable PVC Pelletizing Machine

Babban bayanan fasaha na nau'ikan nau'ikan nau'ikan tagwayen dunƙule extruder pelleitizing inji

| Nau'in samfurin | Jerin | Diamita na Ganga (mm) | Diamita Tsararru (mm) | Rufe L/D | gudun dunƙule n(r/min) | Babban ikon mota (Kw) | Matsakaicin karfin juyi T (Nm) | Ƙididdiga mai ƙarfi (T/A3) | Ƙarfin samarwa na yau da kullun (kg/h) |

| Saukewa: SJSL20 | A/B | 22 | 21.7 | 32-44 | 500/600 | 4/5.5kw | 30/30 | ||

| Saukewa: SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| Saukewa: SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| Saukewa: SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| Saukewa: SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| Saukewa: SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Takaitaccen Kamfanin

Nanjing Yongjie Qixin Machinery Equipment Co., LtdKafa a 2001, maida hankali ne akan wani yanki na 20,000 murabba'in mita a kan namu ƙasar, tare da wata-wata fitarwa na inji 20sets.Our factory ne certificated zuwa AZ, ISO9001: 2008. The kamfanin mayar da hankali a kan bincike, ci gaba da kuma samar da "high matakin, m, sosai sophisticated jerin samfurin layi daya co-juya "cordwood" twin dunƙule extruder, guda dunƙule extruder, biyu mataki extruders da kuma na'urorin pelletizing filastik ta atomatik.Mun ba abokan ciniki samfuran farko-farko tare da “ƙarfi mai ƙarfi, haɓakar haɓakawa, adana makamashi da samfuran kare muhalli.The musamman tsara dunƙule tsarin ya samu nasara ga "daya mataki siffata" a kan da yawa irin kayayyakin, da aka yadu amfani a aluminum hada farantin, XPS kumfa farantin, WP farantin, PP, PE takardar masana'antu, da dai sauransu.

Yadda za a zabi inji don pellet filastik?

1. Kawai gaya mana mugun tsarin ku?

2. Fitowar ku da ake tsammani a cikin awa ɗaya na mahcine