50-80kg / H Yas Extruder PET Pelletizing Tshuab Dej Strand Hom

| Ntsia Hlau Tsim: | Twin Ntsia Hlau Extruder | Daim ntawv thov: | Pet Recycled Bottle Flake |

|---|---|---|---|

| Vacumm: | 3 kwv | Ntsia Hlau Diameter: | 50.5mm ib |

| Ntsia Hlau Khoom: | W6Mo5Cr4V2 | Lub cev muaj zog: | 55 kwv |

| Rpm: | 300 | Muaj peev xwm: | 50-80kg / h |

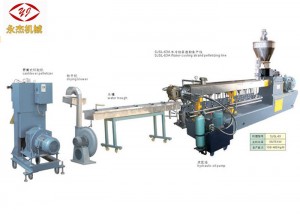

50-80kg / h Yas Extruder Tsiaj Recycling Granulating Kab PET Pelletizing Tshuab

Nanjing Yongjie pib ua dej strand ntxaib ntsia hlau extruder pelletizing tshuab txij thaum 2001, peb ntxaib ntsia hlau extruders yog dav siv rautswj kev hloov kho, degradab le master batch, anti-flame master batch thiab lwm yam.

Dej strand yas pelletizing tshuab daim ntawv thov

Kev txhawb zog thiab kev hloov kho:filling iav fiber los yog carbon fiber rau![]() P, PA, PBT, ABS, AS, POM, PPS, PET thiab lwm yam.

P, PA, PBT, ABS, AS, POM, PPS, PET thiab lwm yam.

Compounding thiab blending:PC + ABS, PA, + ABS, PP + EPDM, PA + EPDM, PP + SBS, thiab lwm yam.

Filling kev hloov kho:Caco3, Talc, Titanium, carbon dub rau PVC, PE, PP, EVA thiab lwm yam.

Cov khoom siv cable:LDE, HDPE, LLDPE, MDPE, tsav yeeb nkab, cov khoom siv rwb thaiv tsev, cov khoom sib txuas, cov khoom siv cable, cov khoom siv thermal contraction thiab lwm yam.

Khoom siv tshwj xeeb:PPR yeeb nkab compounds, PE crosslinking tube khoom, luam yeeb lim cov khoom, acetable fiber ntau thiab lwm yam.

Thick xim masterbatch:PE, ABS, PS, EVA, PET, PP + pigment + additives, thiab lwm yam.

Flaming retarding khoom:PVC, PP, PA, ABS, EVA, PBT + hluav taws kub retardant, thiab lwm yam

Tshwj xeeb ua haujlwm masterbatch:ob chav tiv thaiv masterbatch, antistatic masterbatch, anti-bacteria masterbatch, thermal rwb thaiv tsev masterbatch, hypothermia khoom thiab lwm yam

Biodegradable masterbatch:PP, PE, PS + starch + additives thiab lwm yam.

Cov ntsiab lus ceev ntawm lub tshuab

Txoj kab uas hla:¢50.5mm ib

L/D:44:1

Kev taw qhia ntawm kev sib hloov: Kev sib hloov

Ntsia Hlau & Khoom: W6Mo5Cr4V2(6542 #) kev kub ceev cuab yeej hlau uas tau kho los ntawm lub tshuab nqus tsev hardening txheej txheem nrog lub hardness ntawm qhov chaw yogHRC58-62.Molding los ntawm nplooj siab sib tsoo tshuab.Kev huv huv yog zoo dua li cov khoom tawm ntawm cov txheej txheem ib txwm muaj.

Core qag:High quality alloy steel40CrNiMouas muaj siab tenacity thiab durability.Nws tau raug kho los ntawm cov txheej txheem hardening thiab tempering.

1).Qauv:Covua ntejseem ua hauj lwm rau lub ntsiab pub, lubthib tsibseem yog teem rau venting lawm thiab covthib kaumntu tau teeb tsa rau lub tshuab nqus tsev, lwm qhov yog thaiv.

2).Khoom siv: Cov khoom ntawm lub thoob yog ua los ntawm45#forged steel nrog abrasion-resistantalloy 101 (Ni-Fe-Cr-W) nyob rau hauv uas du thiab puas resistant.Lub hardness yogHRC60-64.

3).Cua sov: Txais ntau kauj ruam hom hluav taws xob cua sov.Qhov thib ib thiab thib ob cheeb tsam thiab lub tshuab taub hau cheeb tsam yog cam khwb cia tooj liab rhaub thiab lwm yam yog cam khwb cia txhuas rhaub.Lub zog cua sov tag nrho yog28 kwvthiab lub peev xwm cua sov max txhua ntu tuaj yeem ncav cuag500 ℃.

4).Txias: Txais cov dej txias txias hauv lub thoob thiab kais dej txias txoj kev sab nraum lub thoob.Cov kav dej ntws yog ua los ntawm cov hlau tsis muaj steel thiab cov dej hauv cov dej ntws tswj cov li qub yog stainless li qub.

Hom ntawm electromagnetic valve yogDANFOSS.

5).Ntev:190 * 11 = 2090 hli

Scope ntawm kev muab khoom:

| Tsis muaj. | Cov ntsiab lus | Chav tsev | Ntau | Cov cim |

| 1 | Twin ntsia hlau extrusion system | teeb | 1 | |

| 1.1 | Pub noj system | teeb | 1 | 0.75 kwm |

| 1.2 | SJ-65 Twin ntsia hlau extruder | teeb | 1 | 36:1 qw |

| 1.3 | Lub tshuab nqus tsev vacuum | teeb | 2 | 1.5 kwv |

| 1.4 | Dej cycling system | teeb | 1 | 0.55 kwm |

| 1.5 | Tsis siv neeg screen changer | teeb | 1 | 1.5 kwv |

| 2 | Hluav taws xob txee | teeb | 1 | |

| 3 | Dej-strand auxiliary system | teeb | 1 | |

| 3.1 | Tuag taub hau | teeb | 1 | |

| 3.2 | Lub pas dej | teeb | 1 | 4M |

| 3.3 | Lub tshuab ziab khaub ncaws | teeb | 2 | 1.5 kwv |

| 3.4 | Pelletizer | teeb | 1 | 100kg/h, 2.2kw |

| 3.5 | Cov khoom siv silo | teeb | 1 | |

| 4 | Cov ntaub ntawv | teeb | 1 |

Lub tuam txhab luv

Nanjing Yongjie Qixin Machinery Equipment Co., LtdFounded hauv 2001, npog thaj tsam ntawm 20,000 square metres ntawm peb tus kheej thaj av, nrog cov khoom siv txhua hli ntawm tshuab 20sets.Peb lub Hoobkas muaj ntawv pov thawj rau CE, ISO9001: 2008.Lub tuam txhab tsom rau kev tshawb fawb, kev tsim kho thiab tsim khoom ntawm "theem siab, raug, cov khoom lag luam zoo heev uas sib luag co-rotating "cordwood" ntxaib ntsia hlau extruder, ib qho ntsia hlau extruder, ob theem extruders thiab tsis siv neeg yas pelletizing tshuab.Peb tau muab cov neeg siv khoom ua ntej cov khoom lag luam nrog "muaj zog torque, ntau lawm, kev txuag hluav taws xob thiab cov khoom tiv thaiv ib puag ncig.Cov qauv tsim tshwj xeeb ntsia hlau tau pom zoo rau "ib kauj ruam shaping" ntawm ntau yam khoom, thiab yog siv dav hauv aluminium composite phaj, XPS foaming phaj, WP phaj, PP, PE daim ntawv kev lag luam, thiab lwm yam.

QAULITY yog muab tso rau tom ntej , thiab peb lub Hoobkas muaj ntawv pov thawj rau ISO 9001: 2008 Daim ntawv pov thawj thiab CE.