PLA Biodegradable Pellets Yas Extrusion Tshuab Cua Txias Tuag Lub ntsej muag txiav txoj kev

| Ntsia Hlau Tsim: | Twin Ntsia Hlau Extruder | Daim ntawv thov: | PLA Biodegradable Pellets |

|---|---|---|---|

| Warranty: | Ib Xyoo | Overseas Engineers: | Muaj rau Installation Thiab Comissioning |

| Ntsia Hlau Diameter: | 6 2,4mm | Lub cev muaj zog: | 75 * 90/110/132kw |

| Muaj peev xwm: | 100-300kg / h | Khoom siv: | Pob kws Startch + PLA / PP + additives |

PLA Biodegradable Yas Pellet Tshuab Cua Txias Yas Extrusion Tshuab

Cov ntsiab lus ceev

Lub zog: 75/90/110/132kw xaiv raws li qhov yuav tsum tau ua

Screw txoj kab uas hla: 62.4mm

Cov khoom siv ntsia hlau:W6Mo5Cr4V2(6542#) kev kub ceev cuab yeej steel

Loj: 63mm

Khoom siv:45 #forged steel nrog rau abrasion-resistant alloy101 (Ni-Fe-Cr-W)sab hauv

L/D: 48:1

Cov zis: 200kg / h raws li cov khoom sib txawv, mis thiab tshuab ntawm cov txheej txheem thiab lwm yam.

Txoj kev txiav: cua txias tuag lub ntsej muag yas pellet tshuab yog siv rau wpc yas pellet

Warranty: ib xyoos

Lub sij hawm xa tuaj: 45 hnub tom qab tso nyiaj

Main parameter ntawm tshuab qhov chaw

| Tsis muaj. | Cov ntsiab lus | Chav tsev | Ntau | Cov cim |

| 1 | Kev kub ceev tov khoom | teeb | 1 | 200 L |

| 2 | Screw loader tshuab | teeb | 1 | 1.5 kwv |

| 3 | Twin ntsia hlau extrusion system | teeb | 1 | |

| 3.1 | Pub noj system | teeb | 1 | 1.5 kwv |

| 3.2 | SJ-65 Twin ntsia hlau extruder | teeb | 1 | 75:1 qw |

| 3.3 | Lub tshuab nqus tsev vacuum | teeb | 1 | 2.2 kwm |

| 3.4 | Dej cycling system | teeb | 1 | 0.55 kwm |

| 3.5 | Tsis siv neeg screen changer | teeb | 1 | 1.5 kwv |

| 4 | Hluav taws xob txee | teeb | 1 | PID |

| 5 | Cua txias auxiliary system | teeb | 1 | |

| 5.1 | Tuag taub hau | teeb | 1 | |

| 5.2 | Lub ntsej muag cutter | teeb | 1 | 1.5 kwv |

| 5.3 | ob-theem conveying system | teeb | 1 | 4kw + 4kw |

| 5.4 | Cov khoom siv silo | teeb | 1 | 4 kwv |

| 6 | Cov ntaub ntawv | teeb | 1 |

Ntiaj teb nto moo hom ntawm cov khoom siv hluav taws xob

1).Lub ntsuas kub ntsuas yog JapaneseRKC' meter ', hom ntse, ob chav channel;

2).Lub inverter ntawm extruder yog Japanese sib koom ua lag luamABB

3).Tsawg-voltage apparatus thiab khawm txais yuavSCHNEIDERkhoom;

4).AC contactor txais yuavSIEMENS khoom;

5).Lub cev muaj zog yogSISMENS BEIDE;

6).Cov cua hloov adoptsCHINT cov khoom.Cov khoom lag luam-xeev relays yog los ntawm Asmeskas cov lag luam koom tes;

7).Lub electromagnetic valve txais yuav DenmarkDANFOSS khoom.

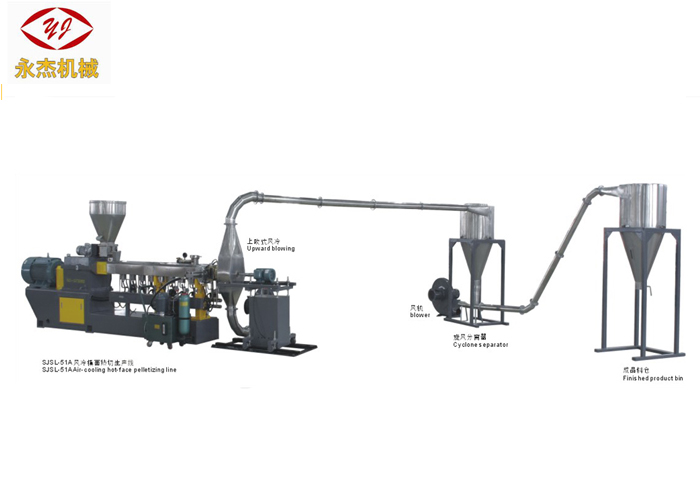

Diam duab ntawm Cua Txias Yas Extrusion Tshuab

Cov ntaub ntawv tseem ceeb ntawm ntau yam qauv ntawm ntxaib ntsia hlau extruder pelleitizing tshuab

| Hom qauv | Series | Lub taub hau (mm) | Ntsia Hlau Diameter (mm) | Ntsia Hlau L / D | ntsia hlau ceev n(r/min) | Main lub cev muaj zog (Kw) | Ntsia Hlau Torque T (Nm) | Kev ntsuas lub zog (T / A3) | Yam khoom muaj peev xwm (kg / h) |

| TSW-36 | A/B/C/D | 36 | 35.6 ib | 32-48 : kuv | 400/600 | 11/15/18.5/22 | 125-225 : kuv | 4.6-8.3 | 30-120 Nws |

| NWS-51 | A/B/C/D | 51 | 50.5 ib | 32-52 : kuv | 500/600 | 45/55/75/90 ib | 405-680 : kuv | 5.1-8.5 | 120-400 Nws |

| TSW-65 | A/B/C/D | 63 | 62.4 ib | 32-64 : kuv | 500/600 | 75/90/110/132 | 680-1200 Nws | 4.8-8.5 Nws | 180-750 Nws |

| NWS-75 | A/B/C/D | 72 | 71 | 32-64 : kuv | 500/600 | 110/132/160/250 | 995-1890 ib | 4.6-8.7 Nws | 300-1200 Nws |

| NWS-95 | A/B/C/D | 94 | 93 | 32-64 : kuv | 500/600 | 250/315/450/550 | 2260-4510 Ib | 4.7-8.7 Nws | 700-2500 Nws |

| TSW-135 | A/B/C/D | 135 | 133 | 32-48 : kuv | 400/500 | 550/750/900/1200 | 6200-10800 Nws | 4.4-7.7 | 1550-6500 Nws |

Lub tuam txhab luv

Nanjing Yongjie Qixin Machinery Equipment Co., LtdFounded hauv 2001, npog thaj tsam ntawm 20,000 square metres ntawm peb tus kheej thaj av, nrog cov khoom siv txhua hli ntawm tshuab 20sets.Peb lub Hoobkas tau ntawv pov thawj rau CE, ISO9001: 2008.

Lub tuam txhab tsom mus rau kev tshawb fawb, kev loj hlob thiab kev tsim khoom ntawm "theem siab, muaj tseeb, cov khoom lag luam zoo sib xws thaum sib tw co-rotating "cordwood" ntxaib ntsia hlau extruder, ib leeg ntsia hlau extruder, ob theem extruders thiab tsis siv neeg yas pelletizing tshuab.Peb tau muab cov neeg siv khoom ua ntej cov khoom lag luam nrog "muaj zog torque, ntau lawm, kev txuag hluav taws xob thiab cov khoom tiv thaiv ib puag ncig.Cov qauv tsim tshwj xeeb ntsia hlau tau pom zoo rau "ib kauj ruam shaping" ntawm ntau yam khoom, thiab yog siv dav hauv aluminium composite phaj, XPS foaming phaj, WP phaj, PP, PE daim ntawv kev lag luam, thiab lwm yam.

QAULITY yog muab tso rau tom ntej, thiab peb lub Hoobkas muaj ntawv pov thawj rauISO 9001: 2008 Daim ntawv pov thawjthiabCE.

Yuav ua li cas xaiv tshuab rau yas pellet?

1. Cia li qhia peb koj cov qauv ntxhib, xws li 50% PE + 50% ntoo fiber ntau + additives thiab lwm yam.

2. Koj xav tau cov zis ib teev ntawm mahcine

Pob ntawm lub tshuab

1. Hiav txwv tsim nyog ntawm zaj duab xis los yog npuas zaj duab xis

2. Ntoo lub thawv lossis ncej raws li tus neeg yuav tsum tau ua