ABB Inverter Water Ring Pelletizer Twin Screw Extruder Akwụkwọ ikike otu afọ

| Nhazi screw: | Ejima ịghasa Extruder | Ngwa: | PE, PP wdg + caco3 ndochi |

|---|---|---|---|

| Akwụkwọ ikike: | Otu afọ | Etiti oge: | Ụbọchị 30 na-arụ ọrụ mgbe nkwụnye ego gasịrị |

| Dayameta skru: | 50.5mm | Ihe mkpuchi & Barrel: | W6Mo5Cr4V2 |

| moto: | 45kw | Ike: | 100-250kg / h |

ABB Inverter Water Ring Pelletizer Twin Screw Extruder Akwụkwọ ikike otu afọ

Ngwa pelletizer mgbanaka mmiri:

1. PE, Eva wdg + Caco3, okwu, Tio92, ndochi mgbanwe na carbon ojii wdg.

2. LDPE, HDPE, LLDPE, MDPE, drivepipe, ihe mkpuchi ihe, crosslinking, cable cover, thermal contraction pipe material etc.

3. PPR ọkpọkọ ogige, PE crosslinking tube ihe, TPR, TPU thermoplastic elastomer, Eva na ọkụ gbazee nrapado wdg.

4. PE, ABS, PS, EVA masterbatch wdg.

5. ABS, Eva flaming retarding masterbatch wdg.

6. PE, PP, PS ndochi na biodegradable masterbatch, wdg.

Nkọwa ngwa ngwa nke pelletizer mmiri mgbanaka sjsl36

dayameta nke ịghasa: 35.6mm

Ihe ịghasa: W6Mo5Cr4V2

Dayameta Barrel: 36mm

Ihe eji eme gbọmgbọm: W6Mo5Cr4V2

Ike moto: 15kw

Ụdị moto: SIEMENS

L/D:44:1

Mpụta: 30-80kg / h

1).Dayameta: ¢51mm,

2).Nhazi: Akụkụ nke mbụ na-arụ ọrụ maka isi

nri, a na-ahazi ngalaba nke ise maka ikuku ikuku

na ngalaba nke iri ka edobere maka ikuku ikuku na

ndị ọzọ na-egbochi.

2).Ihe: A na-eme ihe nke gbọmgbọm ahụ

38CrMoAl nitriding ígwè.

3).kpo oku: Nabata otutu usoro usoro eletrik

kpo oku.Mpaghara nke mbụ na nke abụọ na igwe

A na-atụba isi mpaghara ikpo ọkụ ọla kọpa na ndị ọzọ

aluminom kpo oku.The ngụkọta kpo oku ike bụ 28kw na

ike kpo oku kacha nke ngalaba ọ bụla nwere ike iru

500 ℃.

4).Ntu oyi: Nabata sistemu mmiri dị nro n'ime

gbọmgbọm na mgbata mmiri jụrụ oyi n'èzí gbọmgbọm.Nke

mgbasa ọkpọkọ na-mere nke igwe anaghị agba nchara na

valvụ na-achịkwa ntinye mmiri bụ valvụ igwe anaghị agba nchara.

Ụdị valvụ electromagnetic bụ DANFOSS.

5) Ogologo: 190*11=2090mm

Oke nke ọkọnọ nke sjsl36 mmiri mgbanaka pelletizer

| Mba. | ọdịnaya | Nkeji | Ọnụọgụ | Akara |

| 1 | 100L igwekota oke ọsọ | setịpụrụ | 1 | |

| 2 | Ejima ịghasa extrusion usoro | setịpụrụ | 1 | |

| 2.1 | Usoro nri | setịpụrụ | 1 | 0,75kw |

| 2.2 | SJ-51 ejima ịghasa extruder | setịpụrụ | 1 | 45kw, 44:1 |

| 2.3 | Sistemụ ikuku ikuku | setịpụrụ | 1 | 1,5kw |

| 2.4 | Usoro ịgba ígwè mmiri | setịpụrụ | 1 | 0,55kw |

| 2.5 | Ihe ngbanwe ihuenyo akpaaka | setịpụrụ | 1 | 1,5kw |

| 3 | Igwe ọkụ eletrik | setịpụrụ | 1 | |

| 4 | Usoro inyeaka mmiri-mgbanaka | setịpụrụ | 1 | |

| 4.1 | Mmiri-mgbanaka anwụ isi | setịpụrụ | 1 | |

| 4.2 | Ihu ihu nwere okporo ụzọ nduzi & mkpuchi | setịpụrụ | 1 | 1.5KW |

| 4.3 | Centrifugal dehydrator | setịpụrụ | 1 | 4KW |

| 4.4 | sieve na-ama jijiji | setịpụrụ | 1 | 0.4KW |

| 4.5 | Ihe nchekwa | setịpụrụ | 1 | |

| 5 | Akwụkwọ | setịpụrụ | 1 |

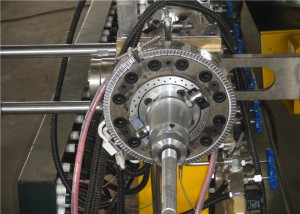

Foto igwe

Isi nkọwa nka na ụzụ nke ụdị igwe pelletizing plastik

| Ụdị ụdị | Usoro | Dayameta Barrel (mm) | Dayameta ịghasa (mm) | Mkpọsa L/D | screw speed n(r/min) | Ike moto (Kw) | Screw torque T(Nm) | Ọnụọgụ torque (T/A3) | Ike mmepụta ihe (kg/h) |

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |