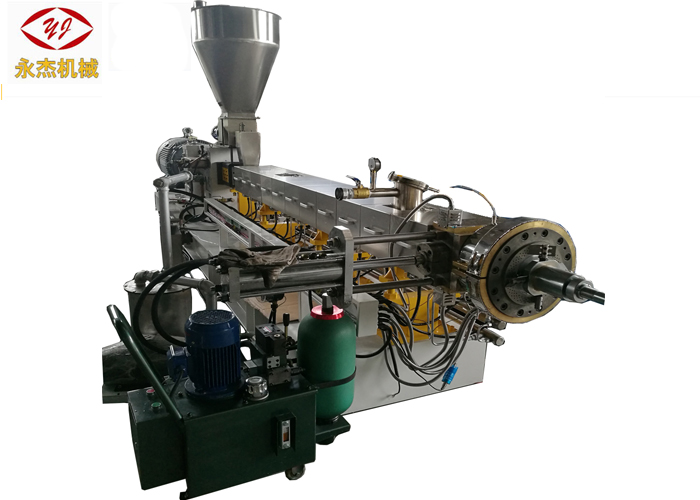

71mm Screw Diameter Die Face Pelletizer PVC Granulating Machine 9 zona panas

| Desain Screw: | Twin Screw Extruder | Aplikasi: | Pvc Pelet Kab |

|---|---|---|---|

| Gearbox: | Torsi Dhuwur 800rpm | Bahan Bakul: | 38CrMoALanti Korosi |

| Diameter sekrup: | 71 mm | Motor: | 280kw |

| Teknik Luar Negeri: | Kasedhiya Kanggo Instalasi lan Latihan | Output: | 500-1000 Kg / jam |

SJSL75D Die Face Pelletizier Twin Screw Extruder PVC Mesin Pelletizing

Air Cooling Die Face PVC Pelletizing Machine Aplikasi

Nglakoni modifikasi:PE, EVA etc + Caco3, Talc, Tio2, PVC, PP, Karbon ireng

Batch master sing bisa didegradasi:PE, PS lsp + pati, aditif lsp

Batch master anti-flake:PE, EVA etc + Sb2o3, Mg(OH)2, AI2(OH)3lsp.

Rincian cepet

Daya: 280 kw

Diameter sekrup: 71 mm

Dhiameter barel: 71.8mm

Gearbox: 800 rpm, rasio reduksi: 1.9: 1

Bahan sekrup & laras:38CrMoAl

Output: 500-1000kg / jam

Cutting cara: air cooling die pasuryan kanggo pvc pelet

Garansi: setaun

Lead time: 45 dina sawise simpenan

Zona pemanasan: 9 zona

Inverter merek: ABB

Gear box: torsi dhuwur, input 1480rpm, output 600rpm, rasio reduksi: 2.5: 1

Barel dawa: 290 * 9 = 2610mm

suku cadang gratis:

| Ora. | Isine | Unit | Jumlah | Tandha |

| 1 | Unsur sekrup | nyetel | ~300 mm | |

| 2 | Output lan input segel lenga poros | potongan | 3 | |

| 3 | Venting kamar segel ring | potongan | 1 | |

| 4 | Sarung tangan asbestos | pasangan | 2 | |

| 5 | Kunci Allen (inner) | nyetel | 1 | 5 bêsik |

| 6 | Kunci Allen (njaba) | nyetel | 1 | 3 bêsik |

| 7 | Cross, Flat screw driver | potongan | 1 saben | 2 bêsik |

| 8 | Screw hoisting ring | potongan | 2 | |

| 9 | Blade | potongan | 30 |

Layanan pra-sales

♦1.Dhukungan pitakon lan konsultasi.♦2.Milih mesin extruder lan mesin sing gegandhengan karo ekonomi lan cocok kanggo pelanggan.

♦3. Nyedhiyakake rincian teknis mesin.

♦4.Nyediakake sarana kinerja nyoba kanggo customer.

♦ 5. Tur pabrik & bantuan surat undhangan yen perlu.

Layanan dodolan

♦ 1. Rekomendasi kahanan engineering dibutuhake kanggo instalasi.

♦2.Komunikasi ing wektu status manufaktur mesin.

layanan sawise-sales

♦1.Insinyur kasedhiya kanggo layanan mesin ing jaban rangkah ing instalasi, komisioning lan latihan.

♦ 2. Ngajokake kanthi rinci informasi pesenan pelanggan.

♦3.Nyediakake layanan pangopènan jangka panjang lan suku cadang.

♦4. Menehi dhukungan teknis kanggo pelanggan kanggo ngembangake produk anyar.

♦5. Nyedhiyakake pangopènan gratis kanggo setahun

Foto sakaNanjing SJSL75D

Data teknis utama macem-macem model mesin pelleitizing extruder kembar

| Tipe model | Seri | Diameter barel (mm) | Diameter sekrup (mm) | Screw L/D | kacepetan meneng n(r/min) | Daya motor utama (Kw) | Torsi sekrup T (Nm) | Rating torsi (T/A3) | Kapasitas produksi khas (kg/jam) |

| SJSL20 | A/B | 22 | 21.7 | 32-44 | 500/600 | 4/5,5 kw | 30/30 | ||

| SJSL-36 | A B C D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A B C D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A B C D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A B C D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A B C D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A B C D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Ringkesan Perusahaan

Nanjing Yongjie Qixin Machinery Equipment Co., LtdFounded in 2001, isine area 20.000 kothak meter ing tanah kita dhewe, karo output saben wulan saka mesin 20sets.Pabrik kita wis sertifikat CE, ISO9001: 2008. Perusahaan konsentrasi ing riset, pangembangan lan produksi "tingkat dhuwur, akurat, produk seri Highly canggih paralel co-puteran" cordwood "extruder meneng kembar, extruder meneng siji, extruders rong tahap lan mesin pelletizing plastik otomatis.Kita wis nyedhiyakake pelanggan produk kelas siji kanthi "torsi kuwat, produksi dhuwur, konservasi energi lan produk perlindungan lingkungan.Struktur meneng dirancang khusus wis temen maujud kasil kanggo "siji langkah mbentuk" ing macem-macem produk, lan digunakake digunakake ing piring aluminium komposit, XPS piring foaming, piring WP, PP, industri sheet PE, etc.