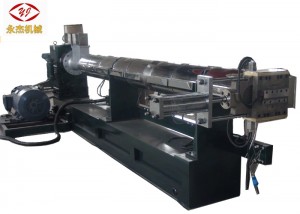

Double Stage PP Extruder Machine, Mesin Reprocessing Plastik Profesional

| Desain Screw: | Tunggal-tunggal Screw Extruder | Aplikasi: | Sampah Plastik Material |

|---|---|---|---|

| Garansi: | Setaun | Insinyur Luar Negeri: | Kasedhiya Kanggo Instalasi lan Comissioning |

| Diameter sekrup: | 250mm / 225mm | Motor: | 280/132 kw |

| Kapasitas: | 400-500kg / jam | Cara nglereni: | Two Stage Water Strand |

Tahap kaping pindho YD250-225Mesin Extruder Sekrup TunggalMesin Pelet Sampah Plastik Kab

Two Stage Extruder

ZL seri, sing loro tataran compounding extruder kasusun saka rong bagéan.Utamane ana telung jinis kombinasi extruder rong tahap:

1.Mesin extruder utama sekrup tunggal - submesin sekrup tunggal

2.Single screw utama pelletizing machine-kembar screw submachine

3.Twin screw utama pelletizing machine-single screw submachine

Rong jinis pisanan digunakake kanggo granulating plastik daur ulang.

Lan jinis katelu kanggo bahan sensitif panas kaya PVC, POM, XLPE etc.

Extruder meneng kembar (SJSL-) ing tataran kapisan kanggo éling shearing apik lan compounding kanggo materi, lan banjur extrusion lan pelletizing dening YD single screw extruder (tataran kapindho).Desain lan struktur sing anyar, ilmiah lan maju bisa ngindhari dekomposisi materi sing disebabake overheating materi

Aplikasi saka Twin-Single Screw Extruder

Batch master ireng karbon

Kabel PVC, botol transparan PVC lan bahan tabung transfusi getih

Bahan kabel crosslink silikon hidrida PE, bahan kabel crosslink peroksida

Bahan campuran kayu-plastik

Polimerida sing sensitif panas.

Rincian cepet

Daya: 280kw kanggo mesin utama YD250, 132kw kanggo extruder skru Ysingle

Diameter sekrup: 71mm kanggo extruder meneng kembar, 180mm kanggo submachine sekrup tunggal

L/D:36:1 & 7:1

Output: 400-500kg / h miturut materi beda, rumus lan teknologi proses etc.

Cutting cara: air cooling mati pasuryan

Garansi: setaun

Lead time: 45 dina sawise simpenan

Rincian bagean utama

| Ora. | Isine | Unit | Jumlah | Tandha |

| 1 | Sistem ekstrusi sekrup kembar | nyetel | 1 | |

| 1.1 | Sistem pakan | nyetel | 1 | 2,2 kw |

| 1.2 | YD250 single screw extruder | nyetel | 1 | 280kw, 40:1 |

| 1.3 | Sistem ventilasi vakum | nyetel | 1 | 2,2 kw |

| 1.4 | Sistem siklus banyu | nyetel | 1 | 0,55 kw |

| 2 | Sistem ekstrusi sekrup tunggal | nyetel | 1 | |

| 2.1 | YD-225 single screw extruder | nyetel | 1 | 132kw, 9:1 |

| 2.2 | Pangowahan layar otomatis | nyetel | 1 | 1,5kw |

| 3 | Kabinet listrik | nyetel | 1 | |

| 4 | Sistem bantu pendingin udara | nyetel | 1 | |

| 4.1 | Kepala mati | nyetel | 1 | |

| 4.2 | Pemotong rai | nyetel | 1 | 1,5kw |

| 4.3 | Silo Siklon | nyetel | 1 | 4kw*2 |

| 4.4 | Saringan vibrator | nyetel | 1 | 0,37kw * 2 |

| 4.5 | Silo | nyetel | 1 | 4kw |

| 5 | Dokumen | nyetel | 1 |

Klausa Bisnis

Lead time: 45 dina sawise simpenan

Engineers kasedhiya kanggo instalasi jaban rangkah, commissioning etc

Istilah pembayaran: 30% simpenan liwat TT, imbangan 70% sadurunge kiriman sawise testing lan mesin kualifikasi ing pabrikan bakul, pembayaran L/C bisa nego

Foto mesin pelletizing pvc mesin ekstrusi plastik

Data teknis utama macem-macem model mesin pelleitizing extruder kembar

| Tipe model | Diameter sekrup (mm) | Screw L/D | kacepetan meneng n(r/min) | Daya motor utama (Kw) | Kapasitas produksi khas (kg/jam) | |

| ZL51-100 | SJSL51 | 50.5 | 20-48 | 500-600 | 37/45 | 150-300 |

| YD100 | 100 | 7-15 | 65-85 | 37 | ||

| ZL60-120 | SJSL60 | 59.5 | 20-44 | 400 | 37/45 | 200-350 |

| YD120 | 120 | 7-15 | 65-90 | 37 | ||

| ZL65-150 | SJSL65 | 62.4 | 20-48 | 400-600 | 55/75 | 250-450 |

| YD150 | 150 | 7-15 | 65-85 | 37/45 | ||

| ZL75-180 | SJSL75 | 71 | 20-44 | 400-600 | 75/90 | 400-650 |

| YD180 | 180 | 7-15 | 65-90 | 45/55 | ||

| ZL95-200 | SJSL95 | 94 | 20-44 | 400-600 | 220/280 | 700-15000 |

| YD200 | 200 | 7-15 | 65-85 | 75/90 | ||

Ringkesan Perusahaan

Nanjing Yongjie Qixin Machinery Equipment Co., LtdFounded in 2001, isine area 20.000 kothak meter ing tanah kita dhewe, karo output saben wulan saka mesin 20sets.Pabrik kita wis sertifikat CE, ISO9001: 2008.

Perusahaan concentrates ing riset, pangembangan lan produksi "tingkat dhuwur, akurat, Highly canggih seri produk podo co-puteran "cordwood" twin screw extruder, single screw extruder, rong tahap extruders lan mesin pelletizing plastik otomatis.Kita wis nyedhiyakake pelanggan produk kelas siji kanthi "torsi kuwat, produksi dhuwur, konservasi energi lan produk perlindungan lingkungan.Struktur meneng dirancang khusus wis temen maujud kasil kanggo "siji langkah mbentuk" ing macem-macem produk, lan digunakake digunakake ing piring aluminium komposit, XPS piring foaming, piring WP, PP, industri sheet PE, etc.