Heavy Duty Master Batch Manufaktur Machine Kanthi Sistem Pelletizing Underwater

| Tipe Plastik: | TPE/TPU/TPR/EVA/PP etc | Garansi: | Setaun |

|---|---|---|---|

| Diameter sekrup: | 71 mm | Bahan Screw & Barrel: | W6Mo5Cr4V2 |

| Motor: | 132/160 kw | Tipe nglereni: | Ing Water Cutting |

| Kapasitas: | 500-900kg / jam | Diameter barel: | 72 mm |

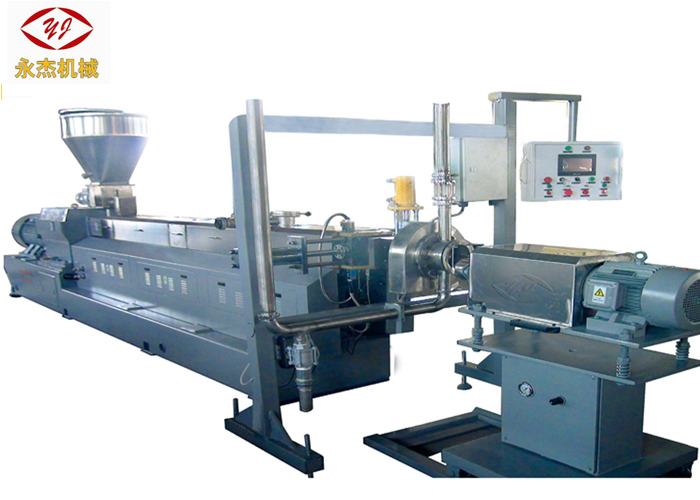

SJSL75B PE PP Micropellets Underwater Twin Screw Plastic Extruder Master Batch Machine

Nanjing Yongjie mesin pelet plastik ing jero banyu minangka teknik khusus lan inovatif kanggo produksi

pelet plastik kualitas hgih, sing nduweni viskositas kurang lan elastisitas dhuwur, utawa duwe wangun khusus, kayata partikel mikro.

Aplikasi tipikal:

1. Poliolefin:LLDPE, LDPE, HDPE, PP, EPDM…

2. Styrolpolymere:PS, ABS…

3. Akrilik:PMMA…

4. Poliasetal:POM…

5. Polikarbonat:PC, PET, PBT, PE…

6. Poliamida:PA6, PA6.6, PA11, PA12…

7. Elastomer Termoplastik:TPE,TPV,TPR,TPEE…

8. Adhesives leleh panas:TPU, EVA, PA, PP

Rincian cepet

Daya: 160 kw

Bahan sekrup: W6Mo5Cr4V2

Bahan laras: 45#baja tempa kanthi paduan tahan abrasi 101 (Ni-Fe-Cr-W) ing jero sing mulus

lan tahan abrasi.Kekerasan yaiku HRC60-64.

L/D:48/52:1

Output: 500-600kg / h miturut materi beda, rumus lan teknologi proses etc.

Revolusi: 0-600rpm;

Rasio reduksi: i = 2,5: 1

Lingkup Pasokan

| Ora. | Isine | Unit | Jumlah | Tandha |

| 1 | mixer kacepetan dhuwur / cooler | nyetel | 1 | 500L |

| 2 | Mesin feed screw | nyetel | 1 | |

| 3 | Sistem ekstrusi sekrup kembar | nyetel | 1 | |

| 3.1 | Sistem pakan | nyetel | 1 | 1,5kw |

| 3.2 | SJ-75 Twin meneng extruder | nyetel | 1 | 132kw, 48:1 |

| 3.3 | Sistem ventilasi vakum | nyetel | 1 | 2,2 kw |

| 3.4 | Sistem siklus banyu | nyetel | 1 | 0,55 kw |

| 3.5 | Pangowahan layar otomatis | nyetel | 1 | 1,5kw |

| 4 | Kabinet listrik | nyetel | 1 | |

| 5 | Sistem mesin tambahan pelletizing ing jero banyu | nyetel | 1 | |

| 5.1 | Sistem katup dump | nyetel | 1 | 2.4KW |

| 5.2 | Ngethok sirah | nyetel | 1 | |

| 5.3 | Sistem pisau pemotong | nyetel | 1 | 5,5KW |

| 5.4 | Katup pneumatik | nyetel | 1 | |

| 5.5 | Dehidrator | nyetel | 1 | 7.5/5.5KW |

| 5.6 | Kabinet listrik | nyetel | 1 | |

| 5.7 | alat vibrator | nyetel | 1 | 0,75KW |

| 5.8 | Sistem transmisi blowing siji tahap | nyetel | 1 | |

| 6 | Mesin timbang & kemasan otomatis | nyetel | 1 | |

| 7 | Dokumen | nyetel | 1 |

Klausa Bisnis

Lead time: 45 dina sawise simpenan

Engineers kasedhiya kanggo instalasi jaban rangkah, commissioning etc

Istilah pembayaran: 30% simpenan liwat TT, imbangan 70% sadurunge kiriman sawise testing lan mesin kualifikasi ing pabrikan bakul, pembayaran L/C bisa nego

Foto Underwater Twin Screw Extruder

Parameter Teknis Utama saka Macem-macem Model

| Tipe model | Seri | Diameter barel (mm) | Diameter sekrup (mm) | Screw L/D | kacepetan meneng n(r/min) | Daya motor utama (Kw) | Torsi sekrup T (Nm) | Rating torsi (T/A3) | Kapasitas produksi khas (kg/jam) |

| SJSL20 | A/B | 22 | 21.7 | 32-44 | 500/600 | 4/5,5 kw | 30/30 | ||

| SJSL-36 | A B C D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A B C D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A B C D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A B C D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A B C D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A B C D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Ringkesan Perusahaan

Nanjing Yongjie Qixin Machinery Equipment Co., LtdFounded in 2001, isine area 20.000 kothak meter ing tanah kita dhewe, karo output saben wulan saka mesin 20sets.Pabrik kita wis sertifikat CE, ISO9001: 2008. Perusahaan konsentrasi ing riset, pangembangan lan produksi "tingkat dhuwur, akurat, produk seri Highly canggih paralel co-puteran" cordwood "extruder meneng kembar, extruder meneng siji, extruders rong tahap lan mesin pelletizing plastik otomatis.Kita wis nyedhiyakake pelanggan produk kelas siji kanthi "torsi kuwat, produksi dhuwur, konservasi energi lan produk perlindungan lingkungan.Struktur meneng dirancang khusus wis temen maujud kasil kanggo "siji langkah mbentuk" ing macem-macem produk, lan digunakake digunakake ing piring aluminium komposit, XPS piring foaming, piring WP, PP, industri sheet PE, etc.

KUALITAS DIPATUHI PISAN , lan pabrik kita wis sertifikat kanggo ISO 9001:2008 lan CE.