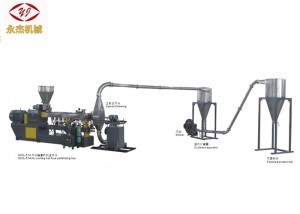

Dhuwur Output 2000kg / H Plastik Extrusion Machine / Peralatan Kanthi High Speed Mixer

| Desain Screw: | Twin Screw Extruder | Aplikasi: | PP PE Kanthi 85% Caco3 |

|---|---|---|---|

| Garansi: | Setaun | Diameter sekrup: | 71 mm |

| L/D: | 52:1 | Gearbox: | 800rpm |

| Motor: | 250kw | Kapasitas: | 2000kg/jam |

2000kg/jam Masterbatch Twin Screw Pelletizing Machine Water Ring Pelletizer Mesin Extruder Plastik

Aplikasi Water Ring Pelletizer:

1. PE, Eva etc + Caco3, Dhiskusi, Tio92, ngisi modifikasi lan karbon ireng etc.

2. LDPE, HDPE, LLDPE, MDPE, drivepipe, bahan isolasi, bahan crosslinking, bahan lapisan kabel, bahan pipa kontraksi termal lsp.

3. Senyawa pipa PPR, bahan tabung crosslinking PE, TPR, elastomer termoplastik TPU, EVA lan adesif leleh panas dll.

4. PE, ABS, PS, EVA masterbatch etc.

5. ABS, EVA murub retarding masterbatch etc.

6. PE, PP, PS Isi lan masterbatch biodegradable, etc.

Rincian cepet pelletizer ring banyu sjsl75D

Diameter sekrup: 71 mm

Bahan sekrup: W6Mo5Cr4V2

Dhiameter barel: 72mm

Bahan laras: W6Mo5Cr4V2

Daya motor: 250kw/315kw

Gearbox: 800 rpm

Merk motor: SIEMENS

L/D:52:1

Output: udakara 2000kg / jam

Laras

1).diameteripun: ¢72 mm

2).Struktur:Ingdhisikbagean dianggo kanggo dipakani utama, ingkaping limabagean diatur kanggo venting alamiah, lan ingkaping sewelasbagean disetel kanggo venting vakum lan liyane diblokir.

3).Bahan: Bahan laras digawe saka45#baja tempa kanthi tahan abrasipaduan 101 (Ni-Fe-Cr-W) ing jero sing alus lan tahan abrasi.Kekerasan yaikuHRC60-64.

4).Pemanasan: Nganggo sawetara langkah format pemanasan listrik.Zona pisanan lan kaloro lan zona sirah mesin yaiku pemanas tembaga lan liyane yaiku pemanas aluminium.Total daya panas punika100kwlan max kapasitas panas saben bagean bisa tekan500 ℃.

5).adhem: Nganggo sistem cooling banyu alus ing tong minyak lan tunyuk banyu cooling cara njaba tong minyak.Pipa sirkulasi digawe saka stainless steel lan katup pengatur aliran banyu yaiku katup tahan karat.

Merk katup elektromagnetik yaikuDANFOSS.

6)Dawane: 290 * 12 = 3480mm

Bagian utama lan paramèter teknis

| Ora. | Isine | Unit | Jumlah | Tandha |

| 1 | Mixer kacepetan dhuwur | nyetel | 1 | 800L |

| 2 | Mesin pakan sekrup | nyetel | 1 | 2,2 kw |

| 3 | Sistem ekstrusi sekrup kembar | nyetel | 1 | |

| 3.1 | Sistem pakan | nyetel | 1 | 2,2 kw |

| 3.2 | SJ-75D Twin meneng extruder | nyetel | 1 | 315kw, 48:1 |

| 3.3 | Sistem ventilasi vakum | nyetel | 1 | 4kw |

| 3.4 | Sistem siklus banyu | nyetel | 1 | 1,5kw |

| 3.5 | Pangowahan layar otomatis | nyetel | 1 | 2,2 kw |

| 4 | Kabinet listrik | nyetel | 1 | |

| 5 | Mesin bantu ring banyu | nyetel | 1 | |

| 5.1 | Kepala mati | nyetel | 1 | |

| 5.2 | Pemotong rai | nyetel | 1 | 2,2 kw |

| 5.3 | Dehidrator | nyetel | 1 | 11 kw |

| 5.4 | Saringan kedher | nyetel | 1 | 0,74 kw |

| 5.5 | Silo produksi | nyetel | 1 | 7,5 kw |

| 6 | Dokumen | nyetel | 1 |

Klausa Bisnis

Lead time: 45 dina sawise simpenan

Engineers kasedhiya kanggo instalasi jaban rangkah, commissioning etc

Istilah pembayaran: 30% simpenan liwat TT, imbangan 70% sadurunge kiriman sawise testing lan mesin kualifikasi ing pabrikan bakul, pembayaran L/C bisa nego

| Tipe model | Seri | Diameter barel (mm) | Diameter sekrup (mm) | Screw L/D | kacepetan meneng n(r/min) | Daya motor utama (Kw) | Torsi sekrup T (Nm) | Rating torsi (T/A3) | Kapasitas produksi khas (kg/jam) |

| SJSL-36 | A B C D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A B C D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A B C D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A B C D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A B C D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A B C D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |