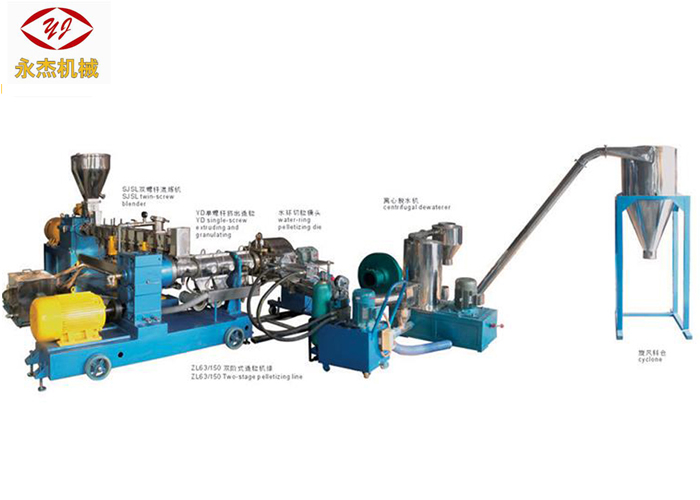

Mesin Pembuatan Granules Plastik Kacepetan Tinggi Water Ring Die Face Cutting Way

| Desain Screw: | Twin Screw Extruder | Aplikasi: | Pelet Plastik Masterbatch ireng |

|---|---|---|---|

| Insinyur Luar Negeri: | Kasedhiya Kanggo Instalasi lan Comissioning | Diameter sekrup: | 35,6 mm |

| Motor: | 18,5kw | Kapasitas: | 30-100kg / jam |

| L/D: | 44:1 | Cara nglereni: | Water Ring Die Face |

SJSL36 PE PP High Filler Masterbatch Manufaktur Machine Plastic Pelletzing Machine

Rincian cepet

Daya: 18,5 kw

Materi sekrup: W6Mo5Cr4V2

Bahan laras:45#baja tempa kanthi paduan tahan abrasi 101 (Ni-Fe-Cr-W) ing jero sing mulus

lan tahan abrasi.Kekerasan yaiku HRC60-64.

L/D:44:1

Output: 20-70kg / h miturut materi beda, rumus lan teknologi proses etc.

Revolusi: 0-600rpm;

Rasio reduksi: i = 2,5: 1

Poros inti: baja paduan kualitas dhuwur40CrNiMosing karo tenacity dhuwur lan kekiatan.Wis diobati kanthi proses hardening lan tempering.

Diameter sekrup: 35.6mm

Diameter laras: 36mm, Ingdhisikbagean dianggo kanggo dipakani utama, ingkaping limabagean diatur kanggo venting alamiah, lan ingkaping wolubagean disetel kanggo venting vakum lan liyane diblokir.

Motor :AC motor, daya:18,5KW, merek:SIEMENS BEIDE;

Pangaturan kacepetan:IngABBkacepetan kontrol inverter;

Gear transmisi: Struktur tri-aksial paralel minangka kombinasi saka

reduksi lan matriks.Gear digawe saka dhuwur

paduan kwalitas (20CrNi2Mo).Iku wis dianggep dening

proses panas sementasi, kelas tliti bisa

tekankaping 6.Iku njamin lumahing waos punikadhuwur

kacepetan, overloading, swara kuranglantorsi dhuwur.

bantalan drive: Merk axletree:NSK Jepang.

Lubrication: Bantalan gear ing kothak gear bakal dadi lenga sing dicemplungake.neng kono

punika lubrication hydraulic ing engagement pindah lan pindah

bantalan.

adhem: Cooling lubricated adopts cangkang lan tabung adhem lan sirkulasi cara cooling banyu.

Cakupan panyedhiya

| Ora. | Isine | Unit | Jumlah | Tandha |

| 1 | Mixer kacepetan dhuwur | nyetel | 1 | 50L |

| 2 | Sistem ekstrusi sekrup kembar | nyetel | 1 | |

| 2.1 | Sistem pakan | nyetel | 1 | 0,75 kw |

| 2.3 | SJ-36 Twin meneng extruder | nyetel | 1 | 15kw, 44:1 |

| 2.4 | Sistem ventilasi vakum | nyetel | 1 | 0,75 kw |

| 2.5 | Sistem siklus banyu | nyetel | 1 | 0,55 kw |

| 2.6 | Pangowahan layar manual | nyetel | 1 | 0,75 kw |

| 3 | Kabinet listrik | nyetel | 1 | |

| 4 | Sistem perakitan ring banyu | nyetel | 1 | |

| 4.1 | Kepala mati | nyetel | 1 | |

| 4.2 | Pemotong rai | nyetel | 1 | 1.5KW |

| 4.3 | Tutup pemotongan cincin banyu | nyetel | 1 | |

| 4.4 | Dehidrator centrifugal | nyetel | 1 | 2.2KW, 3KW |

| 4.5 | Wadah produksi | nyetel | 1 | 3KW |

| 5 | Dokumen | nyetel | 1 |

Foto SJSL36 lab mini extruder mesin pelletizing plastik

Data teknis utama macem-macem model mesin pelletizing extruder kembar

| Tipe model | Seri | Diameter barel (mm) | Diameter sekrup (mm) | Screw L/D | kacepetan meneng n(r/min) | Daya motor utama (Kw) | Torsi sekrup T (Nm) | Rating torsi (T/A3) | Kapasitas produksi khas (kg/jam) |

| SJSL-36 | A B C D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A B C D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A B C D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A B C D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A B C D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A B C D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Ringkesan Perusahaan

Nanjing Yongjie Qixin Machinery Equipment Co., LtdFounded in 2001, isine area 20.000 kothak meter ing tanah kita dhewe, karo output saben wulan saka mesin 20sets.Pabrik kita wis sertifikat CE, ISO9001: 2008.

Perusahaan concentrates ing riset, pangembangan lan produksi "tingkat dhuwur, akurat, Highly canggih seri produk podo co-puteran "cordwood" twin screw extruder, single screw extruder, rong tahap extruders lan mesin pelletizing plastik otomatis.Kita wis nyedhiyakake pelanggan produk kelas siji kanthi "torsi kuwat, produksi dhuwur, konservasi energi lan produk perlindungan lingkungan.Struktur meneng dirancang khusus wis temen maujud kasil kanggo "siji langkah mbentuk" ing macem-macem produk, lan digunakake digunakake ing piring aluminium komposit, XPS piring foaming, piring WP, PP, industri sheet PE, etc.