Interlock Control Plastic Pelletizing Equipment, Two Screw Extruder Machine

| Desain Screw: | Twin Screw Extruder | Aplikasi: | Pengisi Pellet Plastik Masterbatch |

|---|---|---|---|

| Garansi: | Setaun | L/D: | 44:1 |

| Diameter barel: | 51 mm | Motor: | 55kw |

| Kapasitas: | 100-150kg / jam | Kacepetan Revolusi Screw: | 600 rpm |

51mm Filler Masterbatch Manufaktur Machine Air Cooling Twin Screw Extruder

Air Cooling Die Face PVC Pelletizing Machine Aplikasi

Nglakoni modifikasi:PE, EVA etc + Caco3, Talc, Tio2, PVC, PP, Karbon ireng

Batch master sing bisa didegradasi:PE, PS lsp + pati, aditif lsp

Batch master anti-flake:PE, EVA etc + Sb2o3, Mg(OH)2, AI2(OH)3lsp.

Rincian cepet

Daya: 45/55kw pilihan miturut output dibutuhake

Diameter sekrup: 50,5 mm

Bahan sekrup:W6Mo5Cr4V2(6542#) baja perkakas kacepetan dhuwur

Dhiameter barel: 51mm

Bahan laras:45#baja palsu kanthi paduan tahan abrasi101 (Ni-Fe-Cr-W)ing njero

L/D:44:1

Output: 100-150kg / h miturut materi beda, rumus lan teknologi proses etc.

Cara nglereni: pasuryan die cooling online kanggo masterbatch pengisi pe pp lsp.

Garansi: setaun

Lead time: 45 dina sawise simpenan

Kontrol interlock

1).Motor extruder disetel ingkakehan saikikanggo entukpangayoman mateni chainkaro kabinet kontrol listrik.

2).Sistem kontrol motor mesin utamapunika interlocked karosistem kontrol motor feederminangka cara pangayoman bebarengan.

3).Transmisi gearboxlansistem lubricationsing interlocked kanggo pangayoman.

4).Extruder disetel ingoverload tekanankanggo entukpangayoman mateni chainkaro kabinet kontrol listrik.

5).Motor utamadisambungake karopin nilon saka gearbox transmisisupaya minangka kanggo Cut mati pin nilon nalika torsi kakehan.

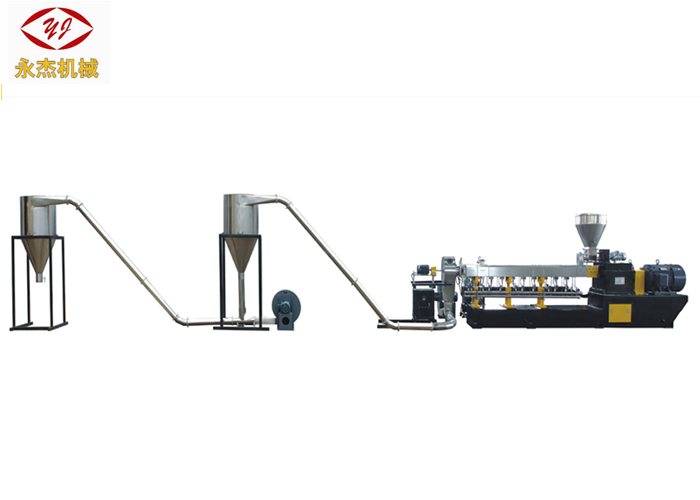

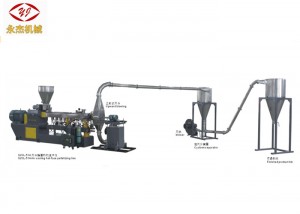

Foto saka Mesin Pabrik Pengisi Masterbatch Mesin Pelet Plastik Pendingin Udara

Data teknis utama macem-macem model mesin pelleitizing extruder kembar

| Tipe model | Seri | Diameter barel (mm) | Diameter sekrup (mm) | Screw L/D | kacepetan meneng n(r/min) | Daya motor utama (Kw) | Torsi sekrup T (Nm) | Rating torsi (T/A3) | Kapasitas produksi khas (kg/jam) |

| SJSL-36 | A B C D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A B C D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A B C D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A B C D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A B C D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A B C D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Ringkesan Perusahaan

Nanjing Yongjie Qixin Machinery Equipment Co., LtdFounded in 2001, isine area 20.000 kothak meter ing tanah kita dhewe, karo output saben wulan saka mesin 20sets.Pabrik kita wis sertifikat CE, ISO9001: 2008.

Perusahaan concentrates ing riset, pangembangan lan produksi "tingkat dhuwur, akurat, Highly canggih seri produk podo co-puteran "cordwood" twin screw extruder, single screw extruder, rong tahap extruders lan mesin pelletizing plastik otomatis.Kita wis nyedhiyakake pelanggan produk kelas siji kanthi "torsi kuwat, produksi dhuwur, konservasi energi lan produk perlindungan lingkungan.Struktur meneng dirancang khusus wis temen maujud kasil kanggo "siji langkah mbentuk" ing macem-macem produk, lan digunakake digunakake ing piring aluminium komposit, XPS piring foaming, piring WP, PP, industri sheet PE, etc.

KUALITAS DIPATUHI PISAN, lan pabrik kita wis sertifikat kanggoISO 9001:2008lanCE.

Paket mesin

1. Segara pantes film utawa film gelembung

2. Kothak kayu utawa pigura miturut syarat pelanggan