ABB Inverter Water Ring Pelletizer Twin Screw Extruder Anni Warranty

| Screw Design: | Didymus stupra Extruder | Applicatio: | PE,PP Etc+caco3 Replens |

|---|---|---|---|

| Warranty: | Unus annus | Tempus ducere: | XXX Days Post Depositum |

| Screw Diameter: | 50.5mm | Materiam stupra & Ferocactus: | W6Mo5Cr4V2 |

| Motor: | 45kw | Capacitas: | 100-250kg/h |

ABB Inverter Water Ring Pelletizer Twin Screw Extruder Anni Warranty

Aqua Ringi Pelletizer Applicatio:

1. PE, Eva etc + Caco3, disputatio, Tio92, impletio modificationis et carbonis nigri etc.

2. LDPE, HDPE, LLDPE,MDPE, drivepipe, materia velit, materia connexio, materia membrana coating, materia contractio fistulae scelerisque etc.

3. PPR fistula composita, PE materia tubi connexionis, TPR, TPU elastomer thermoplasticus, EVA liquefacti tenaces et calida etc.

4. PE, ABS, PS, EVA masterbatch etc.

5. ABS, EVA flammea retardans masterbatch etc.

6. PE, PP, PS implens et biodegradabile masterbatch, etc.

Quick details of sjsl36 aquam anulum pelletizer

Cochlea diametri: 35.6mm

Screw material: W6Mo5Cr4V2

Ferocactus diameter 36mm

Ferocactus materia: W6Mo5Cr4V2

Motor power:15kw

Motor notam: SIEMENS

L/D:44:1

Output: 30-80kg/h*

1).Diameter: 51mm;

2).Structura: Pars prima opera principale

pascens, quinta sectio constituitur ad arcendum naturaliter

et decima ponitur pro vacui instigatione

alii obstruuntur.

2).Materia: Materia dolii factum est

38CrMoAl ensem nitridum.

3).Calefaciens: Adopto plures gradus forma electrica

calefacere.Prima et secunda zona et machina

caput zona ejiciuntur calefacientis aeris et alii conjiciuntur

aluminium calefacientis.Totalis potentia calefactio est 28kw et

ad max calefactio facultatem omnem sectionem attingere potest

500 .

4).Refrigerium: Accipe mollis aqua refrigerandi ratio in

dolium et sonum aquae refrigerationis extra dolium.The

tibiae circulationis fiunt ex ferro immaculato , et

aquae influxus valvulae regulantes sunt valvulae immaculatae.

Notam valvae electromagneticae est DANFOSS.

5) Longitudo: 190*11=2090mm

Copia copiae sjsl36 anuli aquae pelletizer

| Nec. | Contents | Unitas | quantitas | marcas |

| 1 | 100L altus celeritas turpis | set | 1 | |

| 2 | Didymus stupra extrusionem system | set | 1 | |

| 2.1 | Ratio pascendi | set | 1 | 0.75kw |

| 2.2 | SJ-51 Didymus cochlea extruder | set | 1 | 45kw, 44:1; |

| 2.3 | Vacuum ratio instigandi | set | 1 | 1.5kw |

| 2.4 | Aqua cycling systema | set | 1 | 0.55kw |

| 2.5 | Lorem screen mutante | set | 1 | 1.5kw |

| 3 | Electric scrinium | set | 1 | |

| 4 | Anulus aquaticus systematis auxiliaris | set | 1 | |

| 4.1 | Aqua anulus mori caput | set | 1 | |

| 4.2 | Faciem circumdatos cum duce plenas & operculum | set | 1 | 1.5KW |

| 4.3 | dehydrator centrifuga | set | 1 | 4KW |

| 4.4 | Cribrum vibrans | set | 1 | 0.4KW |

| 4.5 | Repono bin | set | 1 | |

| 5 | Documenta | set | 1 |

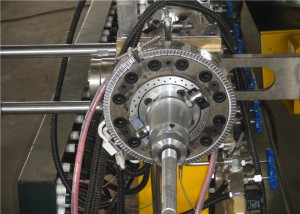

Photo of machina

Main Technical Details of Plastic Pelletizing Machina Exempla

| Exemplar genus | Series | Ferocactus Diameter (mm) | Screw Diameter (mm) | Screw L/D | cochlea celeritate n (r / min) | Principalis potentia motoris (Kw) | Screw torque T(Nm) | Torque rating (T/A3) | Typical productio facultatem (kg/h) |

| SJSL-36 | A B C D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A B C D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A B C D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-9.5 | 180-750 |

| SJSL-75 | A B C D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A B C D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-250 |

| SJSL-135 | A B C D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |