OEM manufacturer Twin Screw Extruder For Lab - Abrasion Resistant Lab Twin Screw Extruder W6Mo5Cr4V2 Screw Material 5.5kw – Yongjie

OEM manufacturer Twin Screw Extruder For Lab - Abrasion Resistant Lab Twin Screw Extruder W6Mo5Cr4V2 Screw Material 5.5kw – Yongjie Detail:

| Screw Design: | Twin Screw Extruder | Application: | Formula Testing Etc |

|---|---|---|---|

| Barrel Diameter: | 22mm | Screw Diameter: | 21.7mm |

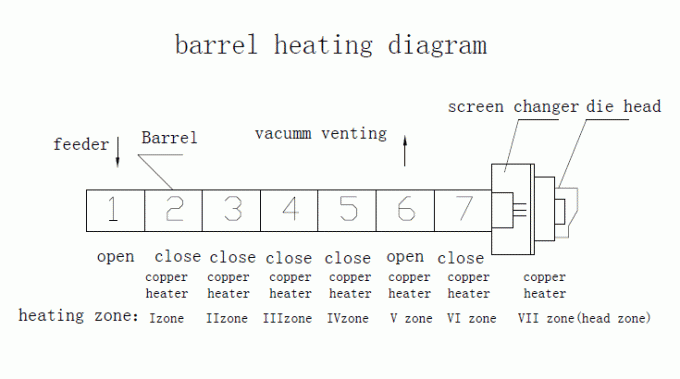

| Motor: | 5.5kw | Barrel Section: | 7 Sections |

| L/D: | 40:1 | Screw Material: | W6Mo5Cr4V2 |

SJSL20 2-15kg Laboratory Twin Screw Extruder Filler Masterbatch Testing Machine

Quick details

Power:5.5kw

Screw material:W6Mo5Cr4V2

Barrel material: 45#forged steel with the abrasion-resistant alloy 101 (Ni-Fe-Cr-W) inside that smooth

and abrasion resistant. The hardness is HRC60-64.

L/D:40:1

Output:20-70kg/h according to different material, formula and technology of process etc.

Revolutions: 0-600rpm;

Reduction ratio: i = 2.5:1

Core axle: High quality alloy steel 40CrNiMo that with high tenacity and durability. It had been treated by the hardening and tempering process.

Screw diameter:21.7mm

Barrel diameter:22mm, The first section works for main feeding, the fifth section is set up for venting naturally, and the ninth section is set up for vacuum venting and others are blocked.

Water stand pelletizing auxiliary machine system

Die head

1). It’s made of 38CrMoAlA, which has been treated by the azotizing on the surface, HV=950~1100;

2). Hole:2pcs-∮4mm

Water sink

1). Width=280mm, depth=200mm, Length=1000mm

2). Three rubber roll brackets.

Dryer

1). Power: 0.26KW, Aluminum fan

2). Made of stainless steel.

Pelletizer

1). Power: 0.75kw,

Inverter speed regulation

0-1480rpm;

2). Capacity:~40kg/h;

Photo of SJSL20 lab mini extruder

Main technical data of various model of twin screw extruder pelletizing machine

| Model type | Series | Barrel Diameter (mm) | Screw Diameter (mm) | Screw L/D | screw speed n(r/min) | Main motor power(Kw) | Screw torque T(N.m) | Torque rating (T/A3) | Typical production capacity (kg/h) |

| SJSL-20 | A/B | 21.7 | 22 | 32-44 | 400/600 | 4/5.5 | 30 | 4.8 | 2-15 |

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Company Brief

Nanjing Yongjie Qixin Machinery Equipment Co.,Ltd Founded in 2001, covers an area of 20,000 square meters on our own land, with monthly output of machine 20sets. Our factory is certificated to CE, ISO9001:2008.The company concentrates on research, development and production of “high level, accurate, highly sophisticated series product parallel co-rotating “cordwood” twin screw extruder, single screw extruder, two stage extruders and automatic plastic pelletizing machines. We have provided customers first-class products with “strong torque, high production, energy conservation and environmental protection products. The special designed screw structure has realized successfully for “one step shaping” on many kinds of products, and is widely used in aluminum composite plate, XPS foaming plate, WP plate, PP, PE sheet industry, etc.

Product detail pictures:

Related Product Guide:

Cooperation

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and advancement, we'll build a prosperous future together with your esteemed organization for OEM manufacturer Twin Screw Extruder For Lab - Abrasion Resistant Lab Twin Screw Extruder W6Mo5Cr4V2 Screw Material 5.5kw – Yongjie , The product will supply to all over the world, such as: San Francisco, Bangkok, Denver, We warmly welcome domestic and overseas customers to visit our company and have business talk. Our company always insists on the principle of "good quality, reasonable price, the first-class service". We have been willing to build long-term, friendly and mutually beneficial cooperation with you.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.