OEM Supply Lab Extruder Machine - Automatic Corn Starch Biodegradable & Compostable Pellet Extruder Machine 100kg/h Twin Screw Extruder CE Standard – Yongjie

OEM Supply Lab Extruder Machine - Automatic Corn Starch Biodegradable & Compostable Pellet Extruder Machine 100kg/h Twin Screw Extruder CE Standard – Yongjie Detail:

| Screw Design: | Twin Screw Extruder | Plastic Type: | Textrured Protein |

|---|---|---|---|

| Warranty: | One Year | Screw Diameter: | 50.5mm |

| Screw & Barrel Material: | W6Mo5Cr4V2 | L/D: | 24:1 |

| Cutting Type: | Air Cooling Die Face | Capacity: | 100kg/h |

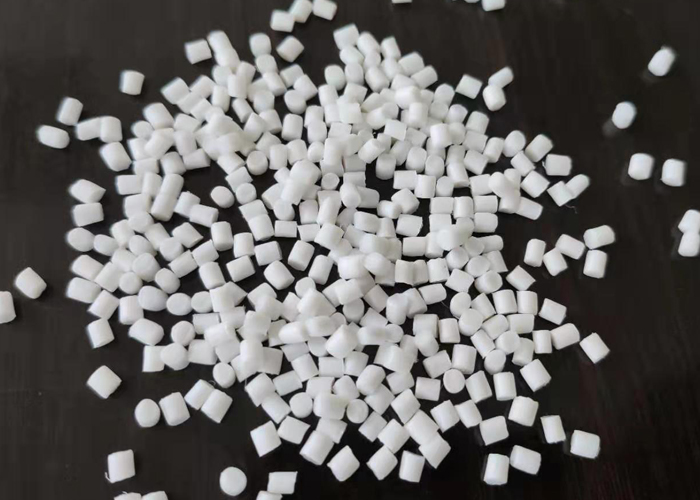

Automatic Corn Starch Biodegradable Pellet Extruder Machine 100kg/h CE Standard

Our biodegredable pellet extruder use PLA, PBAT, corn starch, potato starch, or cassava starch, talc or caco3 etc to make 100% biodegradable and compostable pellets, which is environment-friendly.

Quick details of machine

Screw diameter:62.4mm

Barrel diameter:63mm

Screw & barrel material:W6Mo5Cr4V2

Motor:55kw

L/D:24:1

Length of barrel:190mm*6=1140mm

Cutting way: air cooling die face

ransmission gear: Parallel tri-axial structure is combination of reduction and matrix. The gear is made of high quality alloy (20CrNi2Mo). It had been treated by cementation heat process, the precision grade can reach6th. It guarantee the tooth surface is high speed, overloading, low noise and high torque.

Drive bearing: The brand of axletree: Japanese NSK.

Lubrication: Gear bearings in the gear box will be of oil immersed. There is hydraulic lubrication in the gear engagement and gear bearings.

Cooling: Lubricated cooling adopts shell and tube cooler and circulated water cooling method.

World famous brands of electronic components

1). Temperature control meter is Japanese RKC meter, intelligent type, double channel;

2). The inverter of extruder is ABB;

3). The low-voltage apparatus and the button adopt SCHNEIDER product;

4). AC contactor adopt SIEMENS product;

5). The main motor is SISMENS BEIDE;

6). The air switch adopts CHINT products. The solid-state relays are from American joint venture brand;

7). The electromagnetic valve: adopt Denmark DANFOSS product.

Scope of Supply

| No. | Contents | Unit | Quantity | Marks |

| 1 | Twin screw extrusion system | set | 1 | |

| 1.1 | Feeding system | set | 1 | 1.1kw |

| 1.2 | SJ-51 Twin screw extruder | set | 1 | 55kw, 24:1 |

| 1.3 | Water cycling system | set | 1 | 0.55kw |

| 2 | Electric cabinet | set | 1 | |

| 3 | Documents | set | 1 |

Models of our twin screw extruder

| Model type | Series | Barrel Diameter (mm) | Screw Diameter (mm) | Screw L/D | screw speed n(r/min) | Main motor power(Kw) | Screw torque T(N.m) | Torque rating (T/A3) | Typical production capacity (kg/h) |

| SJSL20 | A/B | 22 | 21.7 | 32-44 | 500/600 | 4/5.5kw | 30/30 | ||

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Photo of machine

Product detail pictures:

Related Product Guide:

Cooperation

Well-run gear, qualified revenue workforce, and superior after-sales companies; We've been also a unified huge loved ones, anyone persist with the organization benefit "unification, determination, tolerance" for OEM Supply Lab Extruder Machine - Automatic Corn Starch Biodegradable & Compostable Pellet Extruder Machine 100kg/h Twin Screw Extruder CE Standard – Yongjie , The product will supply to all over the world, such as: Philadelphia, Indonesia, Bandung, We have been fully aware of our customer's needs. We deliver high quality products, competitive prices and the first class service. We would like to establish good business relationships as well as friendship with you in the near future.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.