PriceList for Lab Scale Twin Screw Extruder Suppliers - 0.25kw Feeder Co Rotating Twin Screw Extruder , Laboratory Scale Extruder Machine – Yongjie

PriceList for Lab Scale Twin Screw Extruder Suppliers - 0.25kw Feeder Co Rotating Twin Screw Extruder , Laboratory Scale Extruder Machine – Yongjie Detail:

| Screw Design: | Co-rotating Parallel Twin Screw Extruder | Application: | Polymer Formula Tesitng |

|---|---|---|---|

| Cooling System: | Soft Non-inoic Distilled Water | Screw&barrel Material: | 38CrMoAL Nitridge Steel |

| Barrel Diameter: | 22mm | Barrel Length: | 120mm * 7section=840mm |

| Capacity: | 2-15kg/h | Feeder: | 0.25kw |

2-15kg/h 20mm Mini Extruder Laboratory Plastic Pelletizing Machine Lab Twin Screw Extruder

Characteristics of twin screw extruder

The screw arrangement are adopted “toy bricks” principle, which assembly according to different machine L/D, different feeding way, different barrel and screw combination, different screen changing and cutting way, different electrical control mode, etc. it meets the features of material and technological process. Give consideration to the plastic universality commonality and appropriability.

Yongjie laboratory mini extruder SJSL20 is widely used among our customers of universities, research center, and factory R&D department for the testing of formula, compounding etc.

Quick details

Power:5.5kw

Screw diameter:21.7mm

Screw material:38CrMoAL

Barrel diameter:22mm

Barrel material:38CrMoAL

Output:around2-15kg/h

Cutting way: water strand, air cooling strand also available

Warranty:one year

Lead time:45 days after deposit

Heating power:16kw

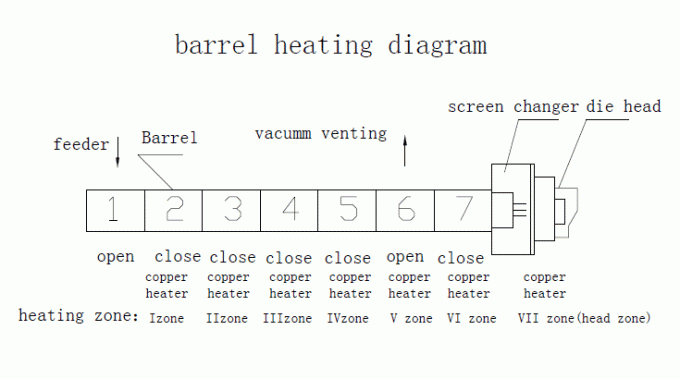

Heating zones: 7zones

Barrel length:120*7=840mm

Control type:PID

Photo of Laboratory Mini Extruder PVC Pelletizing Machine Pvc Cable Extruder

Main technical data of various model of twin screw extruder pelleitizing machine

| Model type | Series | Barrel Diameter (mm) | Screw Diameter (mm) | Screw L/D | screw speed n(r/min) | Main motor power(Kw) | Screw torque T(N.m) | Torque rating (T/A3) | Typical production capacity (kg/h) |

| SJSL20 | A/B | 22 | 21.7 | 32-44 | 500/600 | 4/5.5kw | 30/30 | ||

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Company Brief

Nanjing Yongjie Qixin Machinery Equipment Co.,Ltd Founded in 2001, covers an area of 20,000 square meters on our own land, with monthly output of machine 20sets. Our factory is certificated to CE, ISO9001:2008.The company concentrates on research, development and production of “high level, accurate, highly sophisticated series product parallel co-rotating “cordwood” twin screw extruder, single screw extruder, two stage extruders and automatic plastic pelletizing machines. We have provided customers first-class products with “strong torque, high production, energy conservation and environmental protection products. The special designed screw structure has realized successfully for “one step shaping” on many kinds of products, and is widely used in aluminum composite plate, XPS foaming plate, WP plate, PP, PE sheet industry, etc.

How to choose machine for plastic pellet?

1. Just tell us your rough formula?

2. Your expected output per hour of the mahcine

Product detail pictures:

Related Product Guide:

Cooperation

We are experienced manufacturer. Wining the majority of the crucial certifications of its market for PriceList for Lab Scale Twin Screw Extruder Suppliers - 0.25kw Feeder Co Rotating Twin Screw Extruder , Laboratory Scale Extruder Machine – Yongjie , The product will supply to all over the world, such as: Morocco, Benin, Boston, We're your reliable partner in the international markets of our products and solutions. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade solutions in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market. We're willing to cooperate with business friends from at home and abroad, to create a great future. Welcome to Visit our factory. Looking forward to have win-win cooperation with you.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!