Professional China Single Screw Extruder Plastic Machine - High Performance Single Screw Extruder Machine Long Working Life 200kg/H – Yongjie

Professional China Single Screw Extruder Plastic Machine - High Performance Single Screw Extruder Machine Long Working Life 200kg/H – Yongjie Detail:

| Screw Design: | Single Screw Extruder | Plastic Type: | Plastic Recyclign Material Granules |

|---|---|---|---|

| Warranty: | One Year | Screw Diameter: | 150mm |

| Screw & Barrel Material: | 38CrMoAlA | Motor: | 75kw |

| Cutting Type: | Water Cooling Strand | Capacity: | 200kg/h |

YD150 Recycling Plastic Film Scrap Single Screw Extruder Machine Plastic Granulator Machine

Characteristic of single screw extruder

1.High precision gear box with ability of over loading, smooth transmitting, lower noise

2.Newly designed barrel and screw to ensure well-distributed of material in melting, low melt temperature and high production

3.The screw is made with standard and high precision during process. After treated by gases and nitride the barrel, it possesses strong wear- and corrosion- resisting. For special material, double metals are available for barrel etc.

4.The barrels cooled by lower with super mute working status, less maintenance

5.PID temperature is controlled by Japan temperature control meter with stable and accurate temperature.

6.Two type of die head design: manual and hydraulic type for easy changing and time saving.

7.ABB or other famous brand Inverter speed control for more stable and good performance of machine and easier operation

Quick details of YD150

- The machine L/D=28:1

- Screw diameter: ¢150mm;

- Screw material:38CrMoALA,

d. Barrel material: 38CrMoALA;

- Central height of the screw:900 mm;

- Length of the barrel: 4950 mm

- Heat-resistant capacity of heat sensor in main machine:0-500℃

- Main motor power: 75kw;

- Main machine rotating speed: 17-84 rpm;

- Heating power: 40KW;

- The output : around 200kg/h, (It can be changed according to different materials and technique)

Model of our single screw extruder

| Model type | Screw Diameter (mm) | Screw L/D | Main motor power(Kw) | screw speed n(r/min) | Typical production capacity (kg/h) |

| YD-30 | 30 | 25-33 | 4/5.5 | 3-100 | 2-15 |

| YD-45 | 45 | 20-32 | 5.5/7.5 | 5-84 | 5-40 |

| YD-60 | 60 | 20-32 | 17.5/22 | 5-84 | 15-80 |

| YD-90 | 90 | 20-33 | 30/37 | 5-84 | 25-120 |

| YD-100 | 100 | 20-33 | 37/45 | 5-84 | 45-150 |

| YD-120 | 120 | 20-33 | 45/55 | 5-84 | 75-200 |

| YD-150 | 150 | 20-33 | 75/90 | 5-84 | 150-300 |

| YD-180 | 180 | 20-33 | 90/132 | 5-84 | 200-400 |

| YD-200 | 200 | 20-33 | 110/160 | 5-84 | 250-500 |

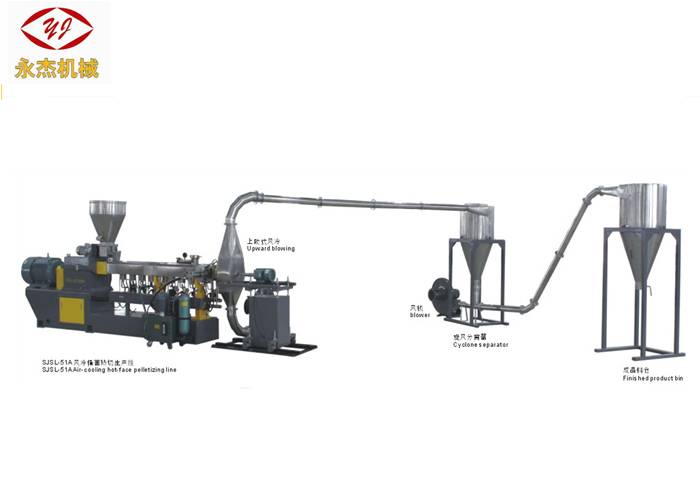

Photo of machine

Company Brief

Nanjing Yongjie Qixin Machinery Equipment Co.,Ltd Founded in 2001, covers an area of 20,000 square meters on our own land, with monthly output of machine 20sets. Our factory is certificated to CE, ISO9001:2008.The company concentrates on research, development and production of “high level, accurate, highly sophisticated series product parallel co-rotating “cordwood” twin screw extruder, single screw extruder, two stage extruders and automatic plastic pelletizing machines. We have provided customers first-class products with “strong torque, high production, energy conservation and environmental protection products. The special designed screw structure has realized successfully for “one step shaping” on many kinds of products, and is widely used in aluminum composite plate, XPS foaming plate, WP plate, PP, PE sheet industry, etc.

QAULITY IS PUT AT THE FIRST , and our factory is certificated to ISO 9001:2008 and CE.

Product detail pictures:

Related Product Guide:

Cooperation

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs for Professional China Single Screw Extruder Plastic Machine - High Performance Single Screw Extruder Machine Long Working Life 200kg/H – Yongjie , The product will supply to all over the world, such as: Gabon, Kyrgyzstan, Paris, We always adhere to follow the honesty, mutual benefit, common development, after years of development and the tireless efforts of all staff, now has perfect export system, diversified logistics solutions, comprehensive meet customer shipping, air transport, international express and logistics services. Elaborate one-stop sourcing platform for our customers!

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.