ABB Inverter Mvura Mhete Pelletizer Twin Screw Extruder Rimwe Gore Warranty

| Screw Design: | Twin Screw Extruder | Application: | PE, PP Etc+caco3 Kuzadza |

|---|---|---|---|

| Warranty: | Gore rimwechete | Nguva Yekutungamira: | 30 Mazuva Ekushanda Mushure meDhipositi |

| Screw Diameter: | 50.5mm | Screw & Barrel Material: | W6Mo5Cr4V2 |

| Motokari: | 45kw | Kugona | 100-250kg/h |

ABB Inverter Mvura Mhete Pelletizer Twin Screw Extruder Rimwe Gore Warranty

Mvura Mhete Pelletizer Application:

1. PE, Eva etc + Caco3, kutaura, Tio92, kuzadza kugadziriswa uye carbon black etc.

2. LDPE, HDPE, LLDPE, MDPE, drivepipe, insulation material, crosslinking material, cable coating material, thermal contraction pipe material etc.

3. PPR pipe compounds, PE crosslinking tube material, TPR, TPU thermoplastic elastomer, EVA uye inopisa yakanyunguduka yakanamatira nezvimwewo.

4. PE, ABS, PS, EVA masterbatch nezvimwe.

5. ABS, EVA flaming retarding masterbatch etc.

6. PE, PP, PS kuzadza uye biodegradable masterbatch, nezvimwe.

Tsanangudzo dzinokurumidza dze sjsl36 mvura mhete pelletizer

Screw dhayamita: 35.6mm

Sirasi zvinhu:W6Mo5Cr4V2

Dhigirii dhayamita: 36mm

Bhareri zvinhu:W6Mo5Cr4V2

Motokari simba: 15kw

Motokari mhando: SIEMENS

L/D:44:1

Kubuda: 30-80kg/h

1).dhayamita: ¢51mm,

2).Chimiro: Chikamu chekutanga chinoshanda kune chikuru

kudyisa, chikamu chechishanu chakagadzirirwa kuburitsa mweya

uye chikamu chegumi chakagadzirirwa vacuum venting uye

vamwe vakavharwa.

2).Material: Zvinhu zvebhodhoro zvinogadzirwa

38CrMoAl nitriding simbi.

3).Kupisa: Tora akawanda nhanho fomati yemagetsi

kudziyisa.Yekutanga uye yechipiri zone uye muchina

head zone vanokandwa hita yemhangura uye vamwe vanokandwa

aluminium hita.Iyo yakazara kupisa simba ndeye 28kw uye

iyo max kudziyisa kugona chikamu chese chinogona kusvika

500 ℃.

4).Kutonhodza: Gamuchira yakapfava mvura yekutonhodza system mu

mbiya uye pombi yemvura inotonhorera nzira kunze kwedhiramu.The

kutenderera mapaipi anogadzirwa nesimbi isina tsvina uye iyo

mvura inoyerera inodzora mavharuvhu mavharuvhu asina tsvina.

Mhando yemagetsi emagetsi vharafu ndeyeDANFOSS.

5)Kureba:190*11=2090mm

Chiyero chekupihwa kwe sjsl36 yemvura mhete pelletizer

| Aihwa. | Zviri mukati | Unit | Quantity | Marks |

| 1 | 100L high speed mixer | set | 1 | |

| 2 | Twin screw extrusion system | set | 1 | |

| 2.1 | Kudyisa system | set | 1 | 0.75kw |

| 2.2 | SJ-51 Twin screw extruder | set | 1 | 45kw, 44:1 |

| 2.3 | Vacuum venting system | set | 1 | 1.5kw |

| 2.4 | Mvura yebhasikoro system | set | 1 | 0.55kw |

| 2.5 | Otomatiki skrini inoshandura | set | 1 | 1.5kw |

| 3 | Magetsi kabati | set | 1 | |

| 4 | Mvura-mhete yekubatsira system | set | 1 | |

| 4.1 | Mvura-mhete kufa musoro | set | 1 | |

| 4.2 | Kucheka kumeso negwara njanji & chivharo | set | 1 | 1.5KW |

| 4.3 | Centrifugal dehydrator | set | 1 | 4KW |

| 4.4 | Vibrating sieve | set | 1 | 0.4KW |

| 4.5 | Bhini rekuchengetedza | set | 1 | |

| 5 | Zvinyorwa | set | 1 |

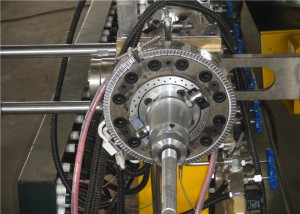

Mufananidzo wemuchina

Main Technical Details ePlastiki Pelletizing Machine Models

| Muenzaniso mhando | Series | Dhiyamita yedhiramu (mm) | Screw Diameter (mm) | Screw L/D | screw speed n(r/min) | Main motor power (Kw) | Sirivha torque T(Nm) | Torque mwero (T/A3) | Yakajairika kugadzira kugona (kg/h) |

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |