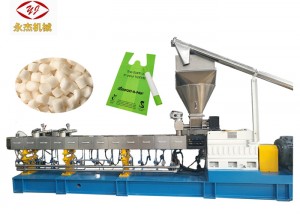

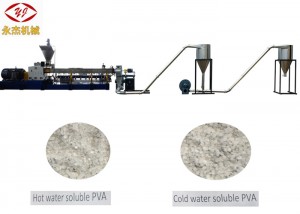

Mochini oa ho Eketsa Plastiki Bakeng sa Corn Starch + PLA/PBAT/PBS/PHA/PCL/PP Biodegradable Plasitc Machine

| Moralo oa Screw: | Twin Screw Extruder | Kopo: | Lithako tsa polasetiki |

|---|---|---|---|

| Tiisetso: | Selemo se le seng | Baenjineri ba mose ho maoatle: | E Fumaneha Bakeng sa ho Instola le ho Komelloa |

| Screw Diameter: | 62.4 limilimithara | Enjene: | 75kw |

| Bolelele ba Lebanta: | 18M Kapa Customized | Bokhoni: | 200-300kg/h |

Lintlha tse potlakileng Matla: 75kw khetho ho latela tlhahiso e hlokahalang Bophara ba Screw: 62.4mm Bophara ba moqomo: 63mm L/D:48/52:1 Sephetho: 30-50kg / h ho latela thepa e fapaneng, foromo le theknoloji ea ts'ebetso joalo-joalo. Mokhoa oa ho itšeha: lebanta le pholileng la moea bakeng sa poone e ka bolang, PLA, hape le ka tlas'a metsi le likhoele tsa metsi bakeng sa PLA ho latela risepe e fapaneng ea PLA. Warranty: selemo se le seng Nako ea ho tsamaisa: Matsatsi a 45 ka mor'a depositi Likarolo tse kholo tsa mochini

| Che. | Litaba | Yuniti | Bongata | Matšoao |

| 1 | Motsoako oa lebelo le phahameng | beha | 1 | 500L |

| 2 | Mochini oa ho kenya li-spiral | beha | 1 | |

| 3 | Sistimi ea "twin screw extrusion". | beha | 1 | |

| 3.1 | Mokhoa oa ho fepa | beha | 1 | 1.1kw |

| 3.2 | SJ-65Twin screw extruder | beha | 1 | 90kw, 48:1 |

| 3.3 | Sistimi ea ho kenya moea ka vacuum | beha | 1 | 2.2kw |

| 3.4 | Sistimi ea libaesekele tsa metsi | beha | 1 | 0.55kw |

| 4 | Khabinete ea motlakase | beha | 1 | |

| 5 | Sistimi e thusang ea ho futhumatsa moea | beha | 1 | |

| 5.1 | Ho shoa hlooho | beha | 1 | |

| 5.2 | Sehlopha sa ho pholisa moea | beha | 1 | limithara tse 18 |

| 6 | Litokomane | beha | 1 |

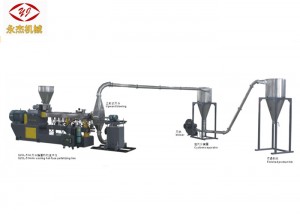

Mochine o monyane oa moea 1Ho shoa hlooho E entsoe ka38CrMoAlA, e 'nileng ea phekoloa ke azotizing holim'a metsi, HV=950-1100; 2.Clebanta la onveying 1).pholileng ea Fans e tsitsitseng holim'a lebanta; 2).16Mbolelele. 3.Pelletizer 1).Matla:2.2kw, taolo ea lebelo la inverter 0-1480rpm; 2).Bokhoni:100kg/h; 3).Tsela ea ho khaola liphaenapole; 4).Granulating e tsamaisoang ke moea. Setšoantšo sa mochini o pholileng oa moea oa sjsl75 oa bioplastic extrusion  Lintlha tsa mantlha tsa tekheniki tsa mefuta e fapaneng ea mochini oa twin screw extruder pelleitizing

Lintlha tsa mantlha tsa tekheniki tsa mefuta e fapaneng ea mochini oa twin screw extruder pelleitizing

| Mofuta oa mohlala | Letoto | Bophara ba moqomo (mm) | Screw Diameter (mm) | Screw L/D | lebelo la screw n(r/min) | Matla a motlakase (Kw) | Screw torque T(Nm) | Tekanyo ea torque (T/A3) | Bokhoni bo tloaelehileng ba tlhahiso (kg/h) |

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Kakaretso ea Khampani Nanjing Yongjie Qixin Machinery Equipment Co.,LtdE thehiloe ka 2001, e akaretsa sebaka sa lisekoere-mithara tse 20,000 naheng ea rona, ka tlhahiso ea khoeli le khoeli ea mochini oa 20sets.Feme ea rona e netefalitsoe ho CE, ISO9001:2008.Khampani e tsepamisitse maikutlo ho lipatlisiso, nts'etsopele le tlhahiso ea "boemo bo phahameng, bo nepahetseng, bo rarahaneng haholo ba lihlahisoa tsa "cordwood" tse pota-potileng "cordwood" twin screw extruder, single screw extruder, li-extruder tse peli tsa sethala le mechine e ikemetseng ea polasetiki ea pelletizing.Re file bareki lihlahisoa tsa boemo ba pele "torque e matla, tlhahiso e phahameng, paballo ea matla le lihlahisoa tsa ts'ireletso ea tikoloho.Sebopeho se khethehileng se entsoeng ka screw se fihletse ka katleho bakeng sa "mohato o le mong oa ho bōpa" lihlahisoa tsa mefuta e mengata, 'me se sebelisoa haholo ka poleiti ea aluminium e kopantsoeng, poleiti ea XPS ea foaming, WP plate, PP, PE sheet sheet, joalo-joalo.

Setšoantšo sa mochini oa polasetiki o ka senyehang oo re o etselitseng bareki ba rona

Mokhoa oa ho khetha mochini bakeng sa pellet ea polasetiki? 1. Re bolelle feela foromo ea hau e thata, joalo ka PBAT/PLA+starch+glycerine + additives joalo-joalo. 2. Tlhahiso ea hau e lebelletsoeng ka hora ea mahcine