2500kg / h PE / PP sareng Caco3 Master Batch Mamchine Cai Ring Pelletizing Mesin 800rpm Extruder Kembar Screw

| Desain screw: | Kembar Screw Extruder | Jenis plastik: | Piaraan Puffed Food Protéin |

|---|---|---|---|

| Garansi: | Sataun | Diaméter screw: | 71 mm |

| Screw & Laras Bahan: | W6Mo5Cr4V2 | Motor: | 315kw |

| Jenis motong: | Hawa cooling maot raray | Kapasitas: | 2000-2500kg / jam |

2500kg / h PE / PP sareng Caco3 Master Batch Mamchine Cai Ring Pelletizing Mesin 800rpm Extruder Kembar Screw

rinci gancang

Daya: 250/280/315kw pilihan nurutkeun kaluaran diperlukeun

Motor: motor AC, Siemens Beide

diaméterna screw: 71mm

Diaméter laras: 71.8mm

L/D: 48/52

Kaluaran: 2000-2500kg / h nurutkeun bahan béda, rumus jeung téhnologi prosés jsb

Cara motong: ring cai kami & hawa cooling mesin pelletizing palastik loba dipaké pikeun masterbatch filler PE PP

Garansi: sataun

Waktos kalungguhan: 45 dinten saatos deposit

SJSL75D Sistim pelletizer ring Cai

1 Paéh sirah

Dijieunna tina38CrMoAlA, nu geus diolah ku azotizing dina beungeut cai, HV=950~1100.

2 Cutter kalawan panutup

1) .Laju kontrol frékuénsi éléktromagnétik;

2).kakuatan motor:2,2kw.

3 Centrifugal dehydrator

1).awak utama stainless steel,15kwkakuatan motor.

4 Ayakan geter

1) .Satu sét stainless steel tabung vibrator sareng dua motor 0.375kw / set,0,75 kwtotal,3Mpanjang.

5 Silo produk

1).Diwangun kubeusi sténlesspemisah siklon sareng kurung,7,5KWkipas, T-joint sarta ngirim pipa

(2) kapasitas Silo: 1,5 ton

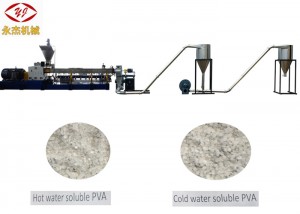

Poto ti2500kg / h PE / PP sareng Caco3 Master Batch Mamchine Cai Ring Pelletizing Mesin 800rpm Extruder Kembar Screw(leuwih model sadia)

Data téknis utama tina rupa-rupa modélextrudermesin pelleitizing screw kembar

| Jenis modél | Runtuyan | Diaméter tong (mm) | Diaméterna screw (mm) | Screw L/D | speed screw n(r/min) | Daya motor utama (Kw) | Torsi screw T (Nm) | Rating torsi (T/A3) | Kapasitas produksi has (kg/h) |

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Ringkes Perusahaan

Nanjing Yongjie Qixin Machinery Equipment Co., LtdDiadegkeun dina 2001, nyertakeun wewengkon 20.000 méter pasagi di darat urang sorangan, kalawan kaluaran bulanan mesin 20sets.pabrik kami geus certificated mun CE, ISO9001: 2008.

Pausahaan concentrates on panalungtikan, ngembangkeun jeung produksi "tingkat tinggi, akurat, produk runtuyan kacida canggih paralel ko-puteran "cordwood" kembar extruder screw, extruder screw tunggal, extruders dua tahap jeung mesin pelletizing palastik otomatis.Kami parantos nyayogikeun produk kelas munggaran pikeun konsumén "torsi anu kuat, produksi tinggi, konservasi énergi sareng produk perlindungan lingkungan.Struktur screw dirancang husus geus sadar hasil pikeun "hiji hambalan shaping" dina rupa-rupa produk, sarta loba dipaké dina plat komposit aluminium, XPS foaming plat, WP plat, PP, industri lambar pe, jsb.

Paket mesin pellet palastik kami (film layak laut atanapi kotak kai nurutkeun sarat)