ABB Inverter Cai Ring Pelletizer Kembar Screw Extruder Garansi Hiji Taun

| Desain screw: | Kembar Screw Extruder | Aplikasi: | PE, PP jsb + caco3 ngeusian |

|---|---|---|---|

| Garansi: | Sataun | Waktos prosés: | 30 Poé Gawé Saatos deposit |

| Diaméter screw: | 50,5 mm | Screw & Laras Bahan: | W6Mo5Cr4V2 |

| Motor: | 45kw | Kapasitas: | 100-250 kg/jam |

ABB Inverter Cai Ring Pelletizer Kembar Screw Extruder Garansi Hiji Taun

Aplikasi Pelletizer Ring Cai:

1. PE, Eva jsb + Caco3, omongan, Tio92, ngeusian modifikasi jeung karbon hideung jsb.

2. LDPE, HDPE, LLDPE, MDPE, drivepipe, bahan insulasi, bahan crosslinking, bahan palapis kabel, bahan pipa kontraksi termal jsb.

3. PPR sanyawa pipe, pe crosslinking tube bahan, TPR, TPU elastomer thermoplastic, Eva jeung panas ngalembereh napel jsb.

4. PE, ABS, PS, EVA masterbatch jsb.

5. ABS, EVA flaming retarding masterbatch jsb.

6. PE, PP, PS keusikan na biodegradable masterbatch, jsb.

rinci gancang sjsl36 ring cai pelletizer

diaméterna screw: 35.6mm

bahan screw: W6Mo5Cr4V2

Diaméter laras: 36mm

Bahan tong: W6Mo5Cr4V2

kakuatan motor: 15kw

Merk motor: SIEMENS

L/D:44:1

Kaluaran: 30-80kg / h

1).Diaméterna: ¢51mm,

2).Struktur: Bagian kahiji lumaku pikeun utama

dahar, bagian kalima diatur pikeun venting alami

jeung bagian kasapuluh diatur pikeun venting vakum jeung

batur diblokir.

2).Bahan: Bahan tong dijieunna tina

38CrMoAl nitriding baja.

3).Pemanasan: Ngadopsi sababaraha léngkah format listrik

pemanasan.Zona kahiji jeung kadua jeung mesin

zone sirah anu matak manaskeun tambaga jeung lianna nu matak

manaskeun aluminium.The total kakuatan pemanasan 28kw jeung

kapasitas pemanasan max unggal bagian bisa ngahontal

500 ℃.

4).Cooling: Ngadopsi sistem cooling cai lemes dina

tong jeung cai keran cooling cara luar tong.The

pipa sirkulasi dijieunna tina stainless steel sarta

inflow cai régulasi valves anu valves stainless.

Merek klep éléktromagnétik nyaéta DANFOSS.

5) Panjangna: 190 * 11 = 2090mm

Lingkup suplai sjsl36 ring cai pelletizer

| No. | eusi | Unit | kuantitas | Tanda |

| 1 | 100L mixer speed tinggi | nyetél | 1 | |

| 2 | Sistim ékstrusi screw kembar | nyetél | 1 | |

| 2.1 | Sistim dahar | nyetél | 1 | 0,75 kw |

| 2.2 | SJ-51 Kembar screw extruder | nyetél | 1 | 45kw, 44:1 |

| 2.3 | Sistim ventilasi vakum | nyetél | 1 | 1,5kw |

| 2.4 | Sistem ngurilingan cai | nyetél | 1 | 0,55 kw |

| 2.5 | Ganti layar otomatis | nyetél | 1 | 1,5kw |

| 3 | Kabinet listrik | nyetél | 1 | |

| 4 | Sistem bantu ring cai | nyetél | 1 | |

| 4.1 | Cai-ring sirah paeh | nyetél | 1 | |

| 4.2 | Pamotong raray sareng rel pituduh & panutup | nyetél | 1 | 1,5KW |

| 4.3 | Dehidrator centrifugal | nyetél | 1 | 4KW |

| 4.4 | Ayakan geter | nyetél | 1 | 0,4KW |

| 4.5 | Panyimpenan bin | nyetél | 1 | |

| 5 | Dokumén | nyetél | 1 |

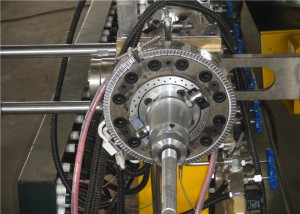

Poto mesin

Rincian Téknis Utama Model Mesin Pelletizing Plastik

| Jenis modél | Runtuyan | Diaméter tong (mm) | Diaméterna screw (mm) | Screw L/D | speed screw n(r/min) | Daya motor utama (Kw) | Torsi screw T (Nm) | Rating torsi (T/A3) | Kapasitas produksi has (kg/h) |

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |