Cai Strand Lab Kembar Screw Extruder Plastik Granulator Mesin 16kw manaskeun Power

| Desain screw: | Kembar Screw Extruder | Pemanas: | Tuang Tambaga |

|---|---|---|---|

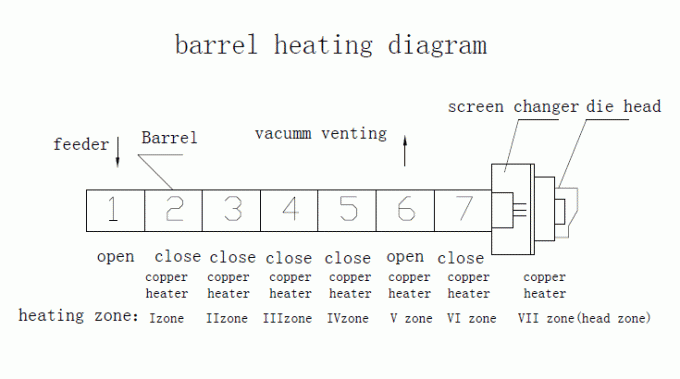

| Daya Pamanas: | 16kw | Diaméter tong: | 22 mm |

| Bahan tong: | 38CrMoALA | Zona pemanasan: | 7 Zona |

| L/D: | 40:1 | Garansi: | Sataun |

SJSL20 7 Pemanasan Zona Lab Kembar Screw Extruder Plastik Mesin Granulating

Ciri tina extruder screw kembar

Susunan screw nu diadopsi "kaulinan bata" prinsip, nu assembly nurutkeun mesin béda L / D, cara dahar béda, laras béda jeung kombinasi screw, layar béda ngarobah sarta motong cara, mode kontrol listrik béda, jsb eta meets fitur tina bahan jeung prosés téhnologis.Mertimbangkeun umumna universality plastik sarta appropriability.

Cai strand palastik aplikasi mesin pelletizing

Penguatan sareng modifikasi:ngeusian serat kaca atawa serat karbon pikeun![]() P, PA, PBT, ABS, AS, POM, PPS, pepet jsb.

P, PA, PBT, ABS, AS, POM, PPS, pepet jsb.

Campuran sareng campuran:PC + ABS, PA + ABS, PP + EPDM, PA + EPDM, PP + SBS, jsb.

modifikasi ngeusian:ngeusian Caco3, Talc, Titanium, karbon hideung pikeun PVC, PE, PP, EVA jsb.

Bahan kabel:LDE, HDPE, LLDPE, MDPE, pipa drive, bahan insulasi, bahan crosslinking, bahan palapis kabel, bahan kontraksi termal jsb.

Bahan aplikasi husus:Sanyawa pipa PPR, bahan tube crosslinking pe, bahan tip filter rokok, bahan serat acetable jsb.

Masterbatch warna kandel:PE, ABS, PS, EVA, pepet, PP + pigmén + aditif, jsb.

Bahan tahan seuneu:PVC, PP, Pa, ABS, EVA, PBT + retardant seuneu, jsb

Masterbatch fungsi husus:masterbatch panyalindungan ganda, masterbatch antistatic, masterbatch anti baktéri, masterbatch insulasi termal, bahan hipotermia jsb

Masterbatch biodegradable:PP, PE, PS + pati + aditif jsb.

rinci gancang

kakuatan: 5.5kw

bahan screw: W6Mo5Cr4V2

Bahan laras:45#baja tempa kalayan alloy tahan abrasion 101 (Ni-Fe-Cr-W) di jero éta lemes

sarta tahan abrasion.Teu karasa nyaéta HRC60-64.

L/D:40:1

Kaluaran: 20-70kg / h nurutkeun bahan béda, rumus jeung téhnologi prosés jsb

Revolusi: 0-600rpm;

Babandingan réduksi: abdi = 2,5: 1

As inti: baja alloy kualitas luhur40CrNiMonu mibanda tenacity tinggi na durability.Éta parantos dirawat ku prosés hardening sareng tempering.

diaméterna screw: 21.7mm

Diaméter laras: 22mm, Thekahijibagian dianggo pikeun dahar utama, étakalimabagian diatur pikeun venting alami, jeungkasalapanbagian diatur pikeun venting vakum sarta séjén diblokir.

Lingkup suplai

| No. | eusi | Unit | kuantitas | Tanda |

| 1 | mixer speed tinggi | nyetél | 1 | 5L |

| 2 | Sistim ékstrusi screw kembar | nyetél | 1 | |

| 2.1 | Sistim dahar | nyetél | 1 | 0,25kw |

| 2.2 | SJ-20 Kembar screw extruder | nyetél | 1 | 5,5kw, 40:1 |

| 2.3 | Sistim ventilasi vakum | nyetél | 1 | 0,75 kw |

| 2.4 | Sistem ngurilingan cai | nyetél | 1 | 0,55 kw |

| 2.5 | Ganti layar manual | nyetél | 1 | |

| 3 | Kabinet listrik | nyetél | 1 | |

| 4 | Sistim bantu nangtung cai | nyetél | 1 | |

| 4.1 | sirah maot | nyetél | 1 | |

| 4.2 | Palung cai | nyetél | 1 | 1 M |

| 4.3 | Pangeringan | nyetél | 1 | 0,26KW |

| 4.4 | Pelletizer | nyetél | 1 | 0,75KW |

| 5 | Dokumén | nyetél | 1 |

Poto SJSL20 lab mini extruder

data teknis utama rupa-rupa modél kembar screw extruder mesin pelletizing

| Jenis modél | Runtuyan | Diaméter tong (mm) | Diaméterna screw (mm) | Screw L/D | speed screw n(r/min) | Daya motor utama (Kw) | Torsi screw T (Nm) | Rating torsi (T/A3) | Kapasitas produksi has (kg/h) |

| SJSL-20 | A/B | 21.7 | 22 | 32-44 | 400/600 | 4/5.5 | 30 | 4.8 | 2-15 |

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Ringkes Perusahaan

Nanjing Yongjie Qixin Machinery Equipment Co., LtdDiadegkeun dina 2001, nyertakeun wewengkon 20.000 méter pasagi di darat urang sorangan, kalawan kaluaran bulanan mesin 20sets.pabrik urang geus certificated mun CE, ISO9001: 2008. Pausahaan concentrates dina panalungtikan, ngembangkeun jeung produksi "tingkat tinggi, akurat, produk runtuyan kacida canggih paralel co-puteran "cordwood" kembar screw extruder, single screw extruder, dua tahap extruders jeung mesin pelletizing palastik otomatis.Kami parantos nyayogikeun produk kelas munggaran pikeun konsumén "torsi anu kuat, produksi tinggi, konservasi énergi sareng produk perlindungan lingkungan.Struktur screw dirancang husus geus sadar hasil pikeun "hiji hambalan shaping" dina rupa-rupa produk, sarta loba dipaké dina plat komposit aluminium, XPS foaming plat, WP plat, PP, industri lambar pe, jsb.