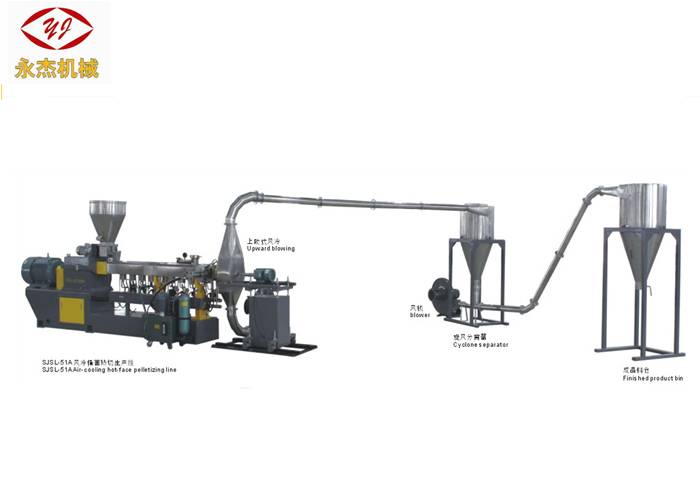

Well-designed Caco3 Masterbatch Machine - TPU TPE TPR EVA PP Caco3 Underwater Pelletizer Upvc Extrusion Machinery – Yongjie

Well-designed Caco3 Masterbatch Machine - TPU TPE TPR EVA PP Caco3 Underwater Pelletizer Upvc Extrusion Machinery – Yongjie Detail:

| Screw Design: | Twin Screw Extruder | Application: | TPR TPE TPU EVA PP+caco3 Filler |

|---|---|---|---|

| Overseas Engineers: | Available For Installation And Comissioning | Barrel Diameter: | 71.8mm |

| Motor: | 160kw | Capacity: | 500-600kg/h |

| L/D: | 48:1 | Material Of Screw: | W6M05Cr4V2 |

Nanjing Yongjie underwater plastic pellet machine is the special and innovative technique for the production of

hgih-quality plastics pellets, which have low viscosity and high elasticity, or have special shape, such as micro-particle.

Typical Application:1.Polyolefine:LLDPE, LDPE, HDPE, PP, EPDM…2.Styrolpolymere:PS, ABS… 3.Acrylharze:PMMA…4.Polyacetale:POM…5.Polycarbonate:PC,PET,PBT, PE…

6.Polyamide:PA6,PA6.6,PA11,PA12…7.Thermoplastics Elastomer:TPE,TPV,TPR,TPEE…8.Hot melt adhesives: TPU, EVA, PA, PP

Quick details

Power:160kw

Screw material:W6Mo5Cr4V2

Barrel material: 45#forged steel with the abrasion-resistant alloy 101 (Ni-Fe-Cr-W) inside that smooth

and abrasion resistant. The hardness is HRC60-64.

L/D:48:1

Output:500-600kg/h according to different material, formula and technology of process etc.

Revolutions: 0-600rpm;

Reduction ratio: i = 2.5:1

Business Clause

Lead time:45 days after deposit

Engineers available for overseas installation, commissioning etc

Payment term:30% deposit via TT, 70% balance before shipment after testing and qualifying machine at seller’s manufacturer, L/C payment are negotiable

Scope of supply

| No. | Contents | Unit | Quantity | Marks |

| 1 | High speed mixer/cooler | set | 1 | 500/1000L |

| 2 | Screw feed machine | set | 1 | |

| 3 | Twin screw extrusion system | set | 1 | |

| 3.1 | Feeding system | set | 1 | 1.5kw |

| 3.2 | SJ-75 Twin screw extruder | set | 1 | 132kw, 44:1 |

| 3.3 | Vacuum venting system | set | 1 | 2.2kw |

| 3.4 | Water cycling system | set | 1 | 0.55kw |

| 3.5 | Automatic screen changer | set | 1 | 1.5kw |

| 4 | Electric cabinet | set | 1 | |

| 5 | Underwater pelletizing auxiliary machine system | set | 1 | |

| 5.1 | Dump valve system | set | 1 | 2.4KW |

| 5.2 | Cutting head | set | 1 | |

| 5.3 | Cutting knife system | set | 1 | 5.5KW |

| 5.4 | Pneumatic valve | set | 1 | |

| 5.5 | Dehydrator | set | 1 | 7.5/5.5KW |

| 5.6 | Electric cabinet | set | 1 | |

| 5.7 | vibrator | set | 1 | 0.75KW |

| 5.8 | One stage blowing transmitting system | set | 1 | |

| 6 | Automatic weighing & packaging machine | set | 1 | |

| 7 | Documents | set | 1 |

Photo

Main technical data of various model of twin screw extruder pelletizing machine

| Model type | Series | Barrel Diameter (mm) | Screw Diameter (mm) | Screw L/D | screw speed n(r/min) | Main motor power(Kw) | Screw torque T(N.m) | Torque rating (T/A3) | Typical production capacity (kg/h) |

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Company Brief

Nanjing Yongjie Qixin Machinery Equipment Co.,Ltd Founded in 2001, covers an area of 20,000 square meters on our own land, with monthly output of machine 20sets. Our factory is certificated to CE, ISO9001:2008.The company concentrates on research, development and production of “high level, accurate, highly sophisticated series product parallel co-rotating “cordwood” twin screw extruder, single screw extruder, two stage extruders and automatic plastic pelletizing machines. We have provided customers first-class products with “strong torque, high production, energy conservation and environmental protection products. The special designed screw structure has realized successfully for “one step shaping” on many kinds of products, and is widely used in aluminum composite plate, XPS foaming plate, WP plate, PP, PE sheet industry, etc.

QAULITY IS PUT AT THE FIRST , and our factory is certificated to ISO 9001:2008 and CE.

Product detail pictures:

Related Product Guide:

Cooperation

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme for Well-designed Caco3 Masterbatch Machine - TPU TPE TPR EVA PP Caco3 Underwater Pelletizer Upvc Extrusion Machinery – Yongjie , The product will supply to all over the world, such as: Bangkok, Boston, Myanmar, The best and original quality for spare parts is a most important factor for transportation. We may stick on supplying original and good quality parts even a little profit earned. God will bless us to do kindness business forever.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.