Wholesale Price China Lab Scale Twin Screw Extruder Factories - Water Strand Lab Twin Screw Extruder Plastic Granulator Machine 16kw Heater Power – Yongjie

Wholesale Price China Lab Scale Twin Screw Extruder Factories - Water Strand Lab Twin Screw Extruder Plastic Granulator Machine 16kw Heater Power – Yongjie Detail:

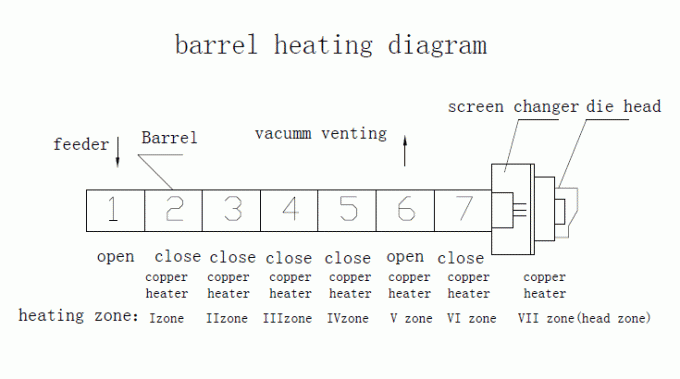

| Screw Design: | Twin Screw Extruder | Heater: | Cast Copper |

|---|---|---|---|

| Heater Power: | 16kw | Barrel Diameter: | 22mm |

| Barrel Material: | 38CrMoALA | Heating Zone: | 7 Zones |

| L/D: | 40:1 | Warranty: | One Year |

SJSL20 7 Heating Zone Lab Twin Screw Extruder Plastic Granulating Machine

Characteristics of twin screw extruder

The screw arrangement are adopted “toy bricks” principle, which assembly according to different machine L/D, different feeding way, different barrel and screw combination, different screen changing and cutting way, different electrical control mode, etc. it meets the features of material and technological process. Give consideration to the plastic universality commonality and appropriability.

Water strand plastic pelletizing machine application

Reinforcement and modification: filling glass fiber or carbon fiber for ![]() P, PA, PBT, ABS, AS, POM, PPS, PET etc.

P, PA, PBT, ABS, AS, POM, PPS, PET etc.

Compounding and blending: PC+ABS, PA,+ABS, PP+EPDM, PA+EPDM, PP+SBS, etc.

Filling modification: filling Caco3, Talc, Titanium, carbon black for PVC, PE, PP,EVA etc.

Cable material: LDE, HDPE, LLDPE, MDPE, drive pipe, insulation material, crosslinking material, cable coating material, thermal contraction material etc.

Special application material: PPR pipe compounds, PE crosslinking tube material, cigarettes filter tip material, acetable fiber material etc.

Thick color masterbatch: PE, ABS, PS, EVA, PET, PP+ pigment + additives, etc.

Flaming retarding material: PVC, PP, PA, ABS, EVA, PBT + fire retardant, etc

Special functional masterbatch: double protection masterbatch, antistatic masterbatch, anti-bacteria masterbatch, thermal insulation masterbatch, hypothermia material etc

The biodegradable masterbatch: PP, PE, PS+ starch + additives etc.

Quick details

Power:5.5kw

Screw material:W6Mo5Cr4V2

Barrel material: 45#forged steel with the abrasion-resistant alloy 101 (Ni-Fe-Cr-W) inside that smooth

and abrasion resistant. The hardness is HRC60-64.

L/D:40:1

Output:20-70kg/h according to different material, formula and technology of process etc.

Revolutions: 0-600rpm;

Reduction ratio: i = 2.5:1

Core axle: High quality alloy steel 40CrNiMo that with high tenacity and durability. It had been treated by the hardening and tempering process.

Screw diameter:21.7mm

Barrel diameter:22mm, The first section works for main feeding, the fifth section is set up for venting naturally, and the ninth section is set up for vacuum venting and others are blocked.

Scope of supply

| No. | Contents | Unit | Quantity | Marks |

| 1 | High speed mixer | set | 1 | 5L |

| 2 | Twin screw extrusion system | set | 1 | |

| 2.1 | Feeding system | set | 1 | 0.25kw |

| 2.2 | SJ-20 Twin screw extruder | set | 1 | 5.5kw, 40:1 |

| 2.3 | Vacuum venting system | set | 1 | 0.75kw |

| 2.4 | Water cycling system | set | 1 | 0.55kw |

| 2.5 | Manual screen changer | set | 1 | |

| 3 | Electric cabinet | set | 1 | |

| 4 | Water stand auxiliary system | set | 1 | |

| 4.1 | Die head | set | 1 | |

| 4.2 | Water trough | set | 1 | 1 M |

| 4.3 | Dryer | set | 1 | 0.26KW |

| 4.4 | Pelletizer | set | 1 | 0.75KW |

| 5 | Documents | set | 1 |

Photo of SJSL20 lab mini extruder

Main technical data of various model of twin screw extruder pelletizing machine

| Model type | Series | Barrel Diameter (mm) | Screw Diameter (mm) | Screw L/D | screw speed n(r/min) | Main motor power(Kw) | Screw torque T(N.m) | Torque rating (T/A3) | Typical production capacity (kg/h) |

| SJSL-20 | A/B | 21.7 | 22 | 32-44 | 400/600 | 4/5.5 | 30 | 4.8 | 2-15 |

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Company Brief

Nanjing Yongjie Qixin Machinery Equipment Co.,Ltd Founded in 2001, covers an area of 20,000 square meters on our own land, with monthly output of machine 20sets. Our factory is certificated to CE, ISO9001:2008.The company concentrates on research, development and production of “high level, accurate, highly sophisticated series product parallel co-rotating “cordwood” twin screw extruder, single screw extruder, two stage extruders and automatic plastic pelletizing machines. We have provided customers first-class products with “strong torque, high production, energy conservation and environmental protection products. The special designed screw structure has realized successfully for “one step shaping” on many kinds of products, and is widely used in aluminum composite plate, XPS foaming plate, WP plate, PP, PE sheet industry, etc.

Product detail pictures:

Related Product Guide:

Cooperation

We thinks what prospects think, the urgency of urgency to act from the interests of a client position of theory, allowing for greater high-quality, reduced processing costs, rates are much more reasonable, won the new and previous consumers the support and affirmation for Wholesale Price China Lab Scale Twin Screw Extruder Factories - Water Strand Lab Twin Screw Extruder Plastic Granulator Machine 16kw Heater Power – Yongjie , The product will supply to all over the world, such as: Southampton, Morocco, Latvia, Over the years, with high-quality products, first- class service, ultra-low prices we win thee trust and favor of customers. Nowadays our products sell all over the domestic and abroad. Thanks for the regular and new customers support. We provide high quality product and competitive price, welcome the regular and new customers cooperate with us!

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.