Wholesale Two Stage Extruder Machine - Horizontal Two Stage Extruder Equipment With Internal Mixer Bucket Elevator – Yongjie

Wholesale Two Stage Extruder Machine - Horizontal Two Stage Extruder Equipment With Internal Mixer Bucket Elevator – Yongjie Detail:

| Screw Design: | Twi-single Screw Extruder | Application: | LDPE+85-90%MDH |

|---|---|---|---|

| Internal Mixer: | 110L | Color: | Any Color |

| Screw Diameter: | 71mm/180mm | Motor: | 132/55kw |

| Capacity: | -500kg Per Hour | Cutting Way: | Two Stage Air Cooling Die Face |

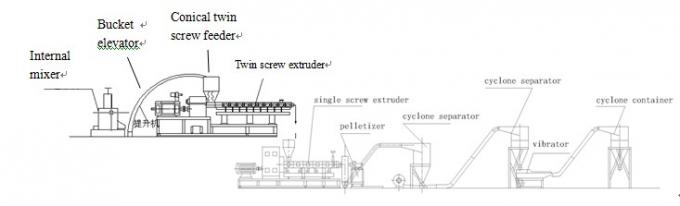

LDPE+MDH ZL75-180 Two Stage Pelletizing Extruder With Internal Mixer Bucket Elevator

Quick details

Power:132kw for twin screw exturder, 55kw for single screw extruder

Screw diameter:71mm for twin screw extruder, 180mm for single screw submachine

L/D:48:1 & 9:1

Output:200-350kg/h according to different material, formula and technology of process etc.

Cutting way: air cooling die face

Warranty:one year

Lead time:45 days after deposit

Transmission gear: Parallel tri-axial structure is combination of reduction and matrix. The gear is made of high quality alloy (20CrNi2Mo). It had been treated by cementation heat process, the precision grade can reach6th. It guarantee the tooth surface is high speed, over loading, low noise and high torque.

Drive bearing: The brand of axletree: NSK.

Lubrication: Gear bearings in the gear box will be of oil immersed. There is hydraulic lubrication in the gear engagement and gear bearings.

Cooling: Lubricated cooling adopts shell and tube cooler and circulated water cooling method.

Scope of supply

| No. | Contents | Unit | Quantity | Marks |

| 1 | 110L Internal mixer | set | 1 | 110L |

| 2 | Bucket elevator | set | 1 | 3kw |

| 3 | Conical twin screw feeder | set | 1 | 11kw |

| 4 | SJ75 twin screw extruder | set | 1 | 132KW, 48:1 |

| 4.1 | Screw feeder | set | 1 | 1.5KW |

| 4.2 | Vacuum venting system | set | 1 | 2.2KW |

| 4.3 | Water cycling system | set | 1 | 0.55KW |

| 5 | YD180 single screw extruder | set | 1 | 55KW, 9:1 |

| 5.1 | Hydraulic screen changer | set | 1 | 1.5KW |

| 6 | Electric cabinet | set | 1 | |

| 7 | Air-cooling assembly system | set | 1 | |

| 7.1 | Die head | set | 1 | |

| 7.2 | Face cutter with cutting wagon | set | 1 | 1.5KW |

| 7.3 | Air cooling cutting cover | set | 1 | |

| 7.4 | Second stage conveying system | set | 1 | 4kw+4kw |

| 7.5 | Vibrating sieve | set | 1 | 0.4KW |

| 7.6 | First stage product container | set | 1 | 4kw |

| 8 | Spare parts | set | 1 | |

| 9 | Documents | set | 1 |

Photo of pvc pelletizing machine plastic extrustion machine

Main technical data of various model of twin screw extruder pelleitizing machine

| Model type | Screw Diameter (mm) | Screw L/D | screw speed n(r/min) | Main motor power(Kw) | Typical production capacity (kg/h) | |

| ZL51-100 | SJSL51 | 50.5 | 20-48 | 500-600 | 37/45 | 150-300 |

| YD100 | 100 | 7-15 | 65-85 | 37 | ||

| ZL60-120 | SJSL60 | 59.5 | 20-44 | 400 | 37/45 | 200-350 |

| YD120 | 120 | 7-15 | 65-90 | 37 | ||

| ZL65-150 | SJSL65 | 62.4 | 20-48 | 400-600 | 55/75 | 250-450 |

| YD150 | 150 | 7-15 | 65-85 | 37/45 | ||

| ZL75-180 | SJSL75 | 71 | 20-44 | 400-600 | 75/90 | 400-650 |

| YD180 | 180 | 7-15 | 65-90 | 45/55 | ||

| ZL95-200 | SJSL95 | 94 | 20-44 | 400-600 | 220/280 | 700-15000 |

| YD200 | 200 | 7-15 | 65-85 | 75/90 | ||

Company Brief

Nanjing Yongjie Qixin Machinery Equipment Co.,Ltd Founded in 2001, covers an area of 20,000 square meters on our own land, with monthly output of machine 20sets. Our factory is certificated to CE, ISO9001:2008.The company concentrates on research, development and production of “high level, accurate, highly sophisticated series product parallel co-rotating “cordwood” twin screw extruder, single screw extruder, two stage extruders and automatic plastic pelletizing machines. We have provided customers first-class products with “strong torque, high production, energy conservation and environmental protection products. The special designed screw structure has realized successfully for “one step shaping” on many kinds of products, and is widely used in aluminum composite plate, XPS foaming plate, WP plate, PP, PE sheet industry, etc.

Product detail pictures:

Related Product Guide:

Cooperation

With a positive and progressive attitude to customer's interest, our company continuously improves our product quality to meet the needs of customers and further focuses on safety, reliability, environmental requirements, and innovation of Wholesale Two Stage Extruder Machine - Horizontal Two Stage Extruder Equipment With Internal Mixer Bucket Elevator – Yongjie , The product will supply to all over the world, such as: Georgia, Hamburg, Ecuador, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.